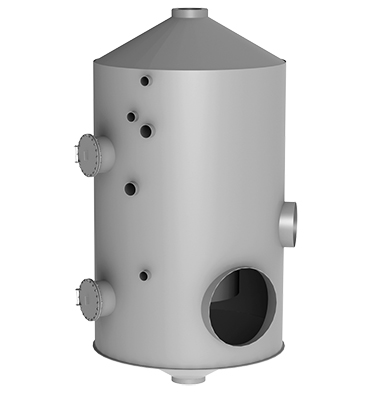

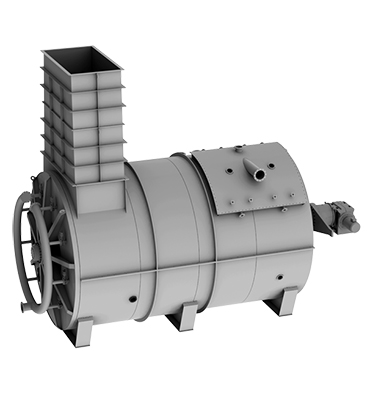

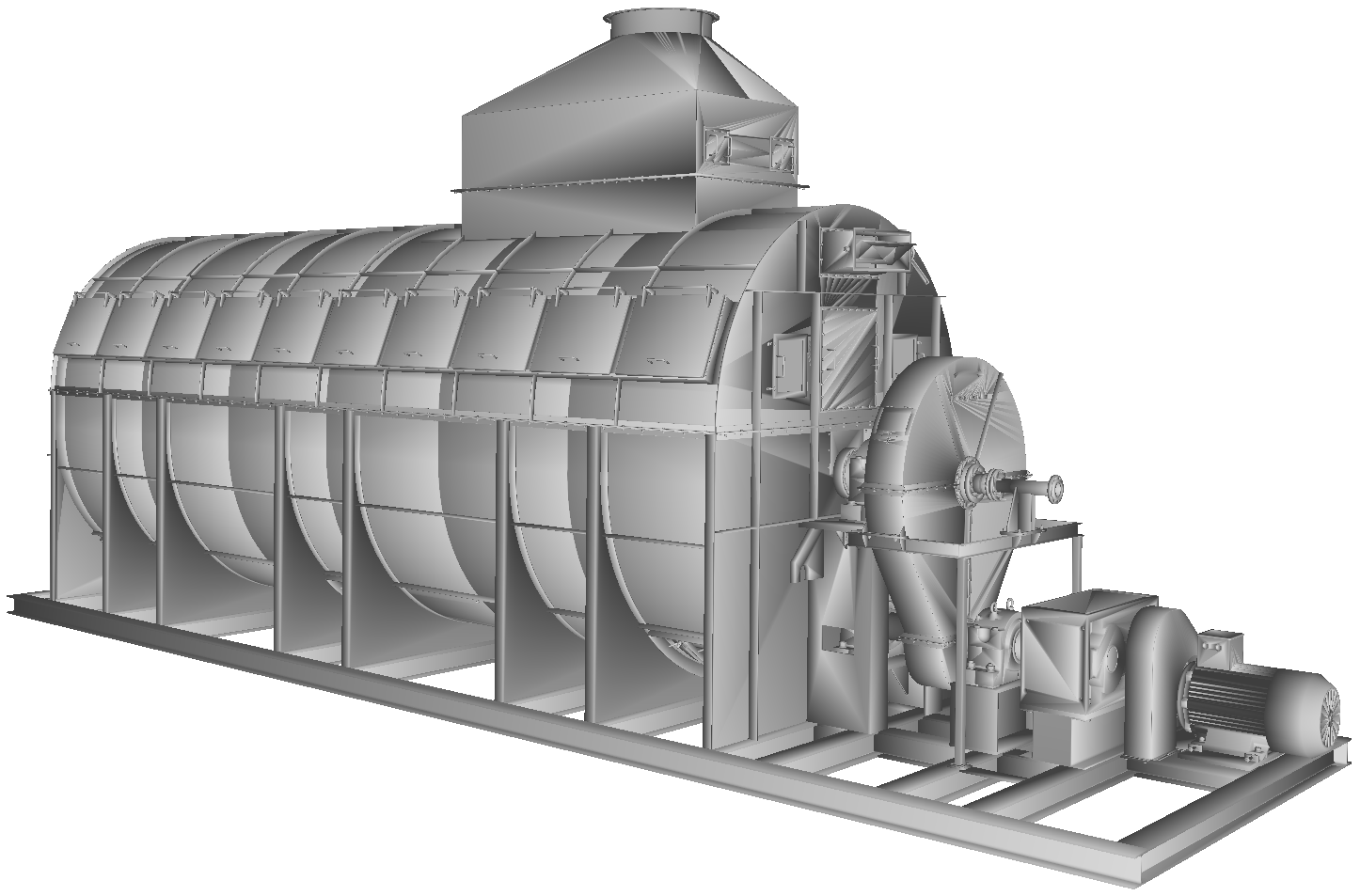

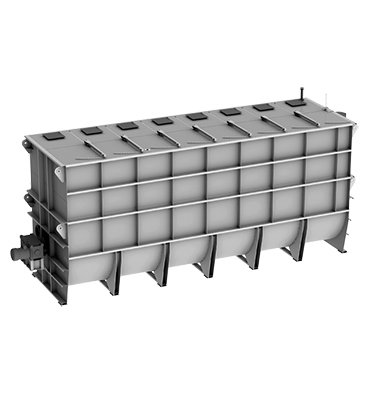

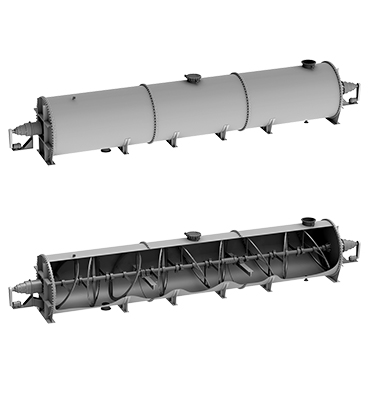

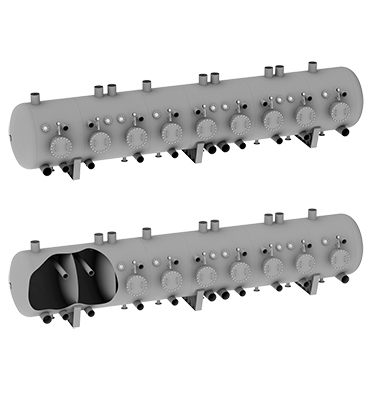

Multi-section condensate collector TS-SKM

Multi-section condensate collector TS-SKM

Designed for collecting condensate from heat exchange equipment, cooling CHP feed condensates and ammonia condensate to a given temperature. Condensate collection is performed on the principle of approximately equal potentials, cooling is stepwise. Used in the processing of sugar beets and raw sugar. The number of sections depends on the temperature of the condensate supplied to the CHP deaerators and can vary from 5 to 12.

Design features

Compliance with specific operating conditions, namely:

high temperatures; work under pressure (vacuum), possibility of water hammer during the start-up period, instability of condensate flow from heat exchange equipment.

Simplicity and reliability of separation devices for distributing condensate in the collector sections.

Simplification of installation and performance of thermal insulation works.

Convenient system for visual control of condensate levels.

Possibility of adaptation to local installation conditions and piping with complex supply.

Possibility of manufacturing two separate multi-section collectors for feed and ammonia condensates or in other versions.

Compactness.

Automation

Automatic mode of maintaining condensate levels.

Full automation of condensate collection, cooling and distribution.

Quality

Cooling of feed condensate for CHP in accordance with the temperature regime of deaerators.

Providing process consumers with ammonia condensate.

Prevention of condensate losses through steam discharge pipelines due to multi-stage reduction of condensate temperature.

Economy

Efficient use of heat and energy resources due to reliable discharge of condensates from heat exchange equipment.

Using condensate heat as a source of secondary energy resources in the form of: self-evaporation steam at the evaporation station, coolants for heating products in heat exchangers; feed water for CHP and diffusion plants.

Reduction of technical water consumption due to the use of ammonia condensates for technological needs.

Minimum maintenance requirements both during production and repair periods.

Characteristics

|

Productivity of the plant, t of beet/day |

2,000 – 12,000 |

|

Number of sections (depending on the type of deaerators and the temperature regime of the evaporation station), pcs. |

5 – 12 |

|

Outer diameter, mm |

1,200 – 2,200 |