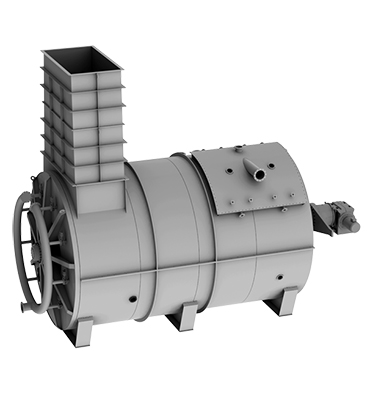

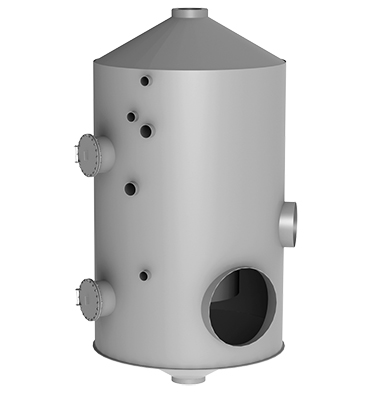

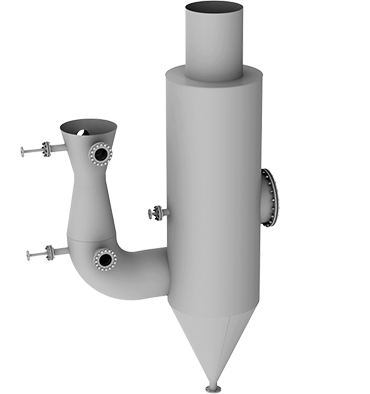

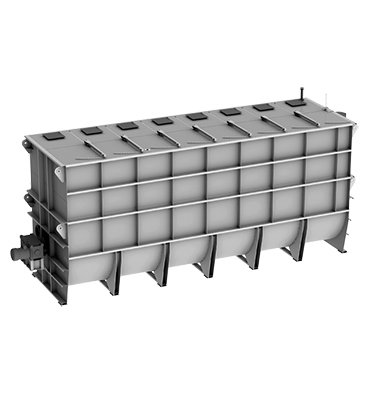

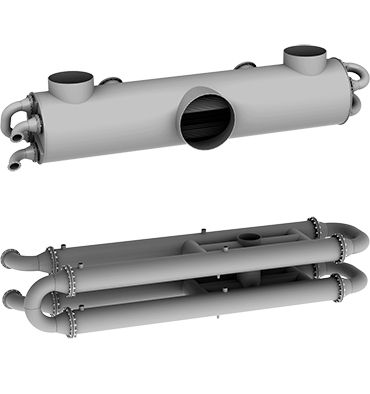

Apparatus I and II saturation TS-AS

Apparatus I and II saturation TS-AS

Designed for maximum removal of non-sugars by adsorption method and obtaining high sedimentation and filtration indicators of juice (apparatus I saturation).

The apparatus II saturation is designed for maximum removal of calcium ions from the solution and additional removal of soluble non-sugars.

Design features

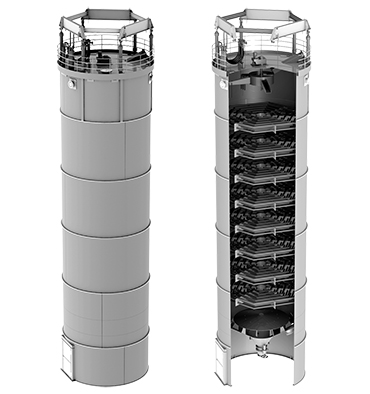

Absence of moving mechanisms and seals.

Absence of a device for forced cleaning of the gas distribution system.

Possibility of adaptation design to the conditions of raw sugar processing.

Absence of stagnant zones inside the apparatus.

Quality

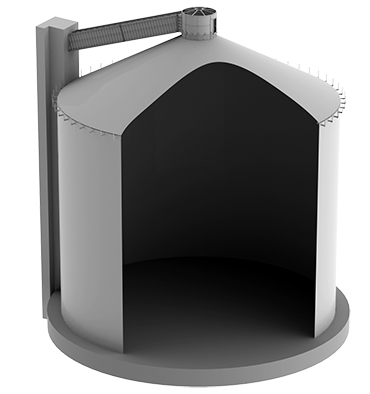

Improvement of sedimentation and filtration properties of juice.

Processing of juice of the 2nd saturation to optimal alkalinity.

Maximum efficiency of juice purification at the 1st saturation is achieved when using the TC-AGDK hot defecation apparatus, as well as reducing the content of soluble calcium salts in juice of the 2nd saturation when using the TC-DDK ripener.

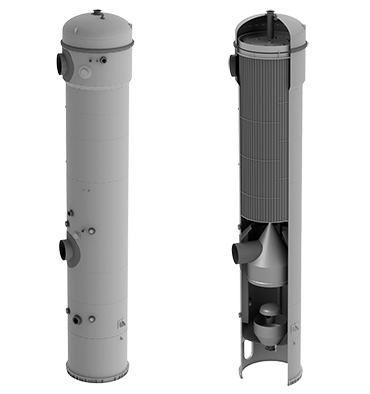

Reliability

Simplicity of the design of gas distribution and flow circulation devices due to the absence of moving mechanisms and seals.

Uninterrupted operation (without scale formation) throughout the entire production season, despite the absence of a device for forced cleaning of the gas distribution system.

High degree utilization of saturation gas.

Natural recirculation of the processed juice flow.

Reduction of heat losses and emissions into the environment.

Automation

Simplification of automation of the technological process at the second saturation due to the absence of stagnant zones inside the apparatus.

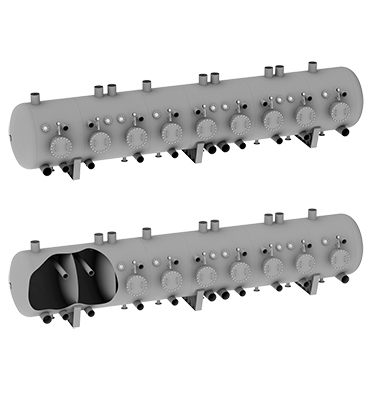

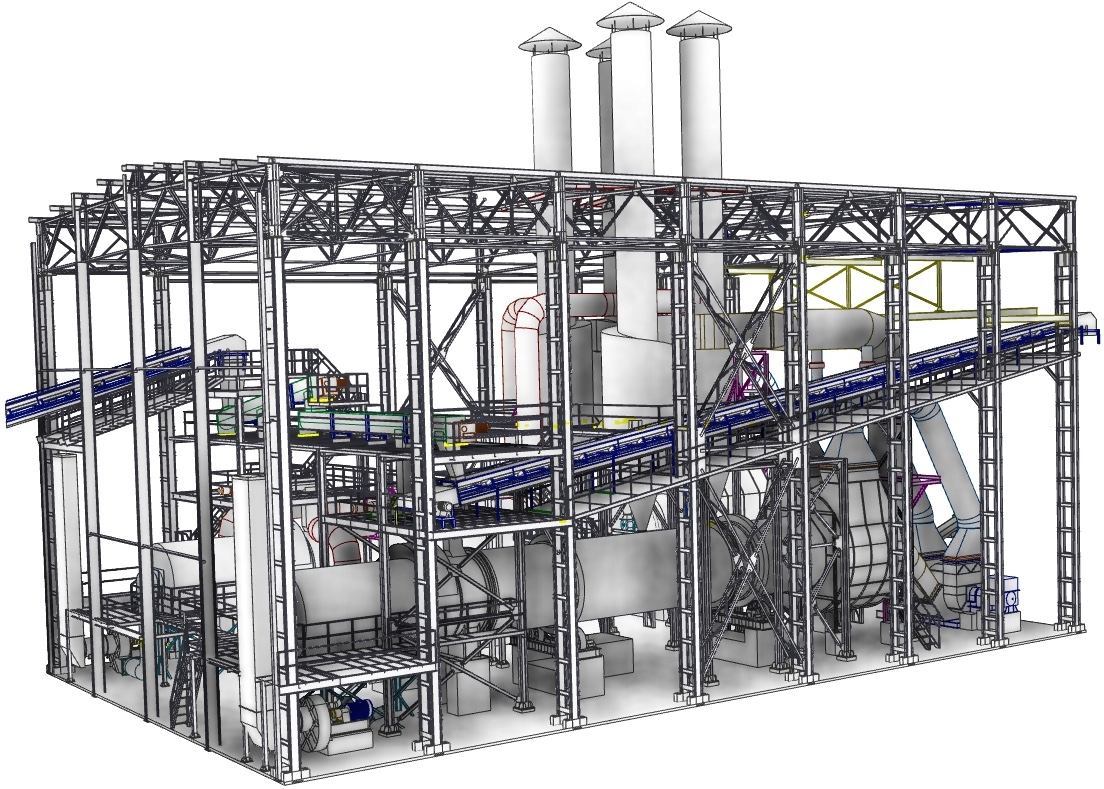

Characteristics

|

Productivity, t/day |

4,500 – 12,000 |

|

Total volume of the device, m³ |

121 – 158 |

|

Working volume of the device, m³ |

42.6 – 68 |

|

Working temperature, °C |

85 – 96 |

|

Process duration, min. |

6 – 11 |

|

Medium reaction, pH |

10.8 – 11.2 |

|

Bubble beam, number of beams |

6 – 12 |

|

Weight, kg |

13,950 – 18,500 |

|

Dimensions – length, mm |

4,200 – 4,450 |

|

Dimensions – width, mm |

3,950 – 4,450 |

|

Dimensions – height, mm |

12,850 – 16,525 |