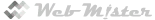

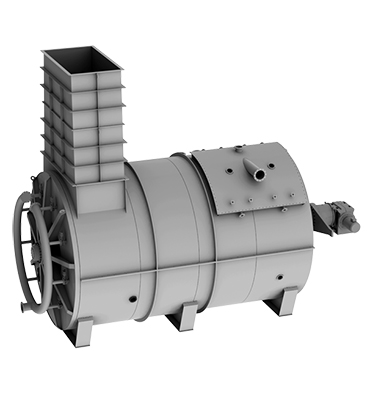

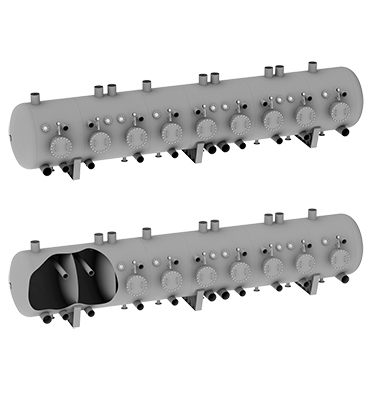

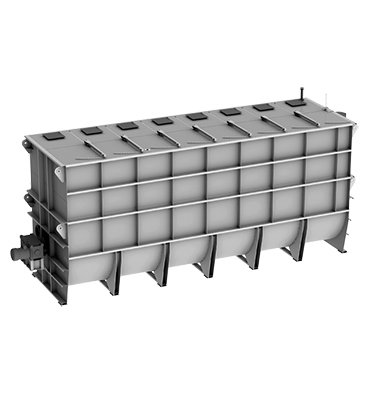

TC-APHD preliminary progressive defecation apparatus, modified by Pankin

Designed for preliminary progressive defecation at the diffusion juice purification station of sugar factories.

Designed for preliminary progressive defecation at the diffusion juice purification station of sugar factories.

Design features

Optimization of internal juice circulation flows due to the design of partitions and rotary dampers.

The possibility of precise flow regulation in a fairly wide range of diffusion juice flow rates.

Quality

Significant improvement in technological indicators of diffusion juice purification.

Increase in speed filtration.

Reliability

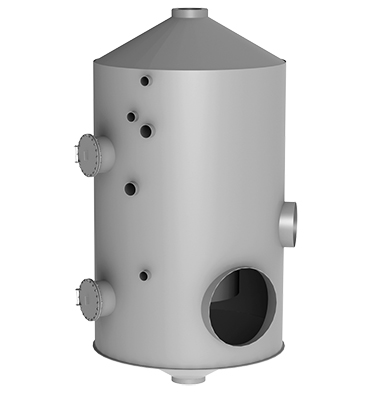

No roller on the middle part of the mixer shaft.

Prevention of juice leakage due to the design of the seal between the mixer shaft and the housing.

Economical

Ensuring productivity of 7,000 – 9,000 tons of beet per day with the possibility of implementing a modern thermal and technological scheme of a sugar factory.

Reduction of lime consumption.

Characteristics

|

Beet productivity, t/day |

7,000 – 9,000 |

|

Type of device |

horizontal |

|

Number of chambers |

8 |

|

Agitator rotation speed, rpm. |

8 … 12.5 |

|

Installed power, kW |

55 |

|

Operating temperature, °C |

45-55 |

|

Working volume (min/max), m³ |

240/280 |

|

Weight of the device (without thermal insulation), kg |

52 200 |

|

Weight of the device filled with juice, kg |

377,700 |

|

Dimensions – length, mm |

14,400 |

|

Dimensions – width, mm |

4,220 |

|

Dimensions – height, mm |

5 930 |