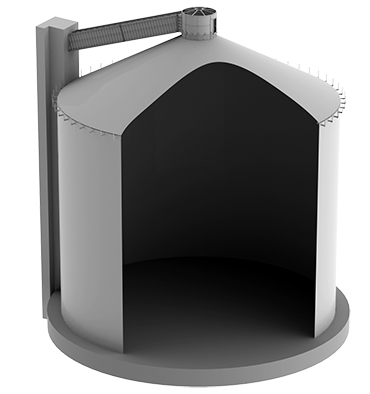

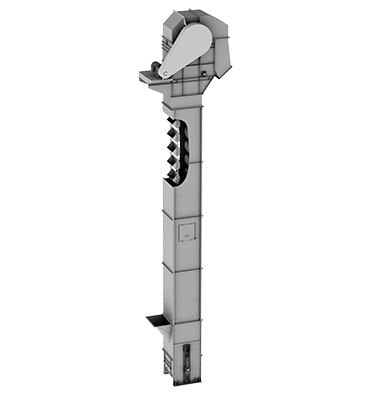

Wet sugar chain elevator TC-ECK

Wet sugar chain elevator TC-ECK

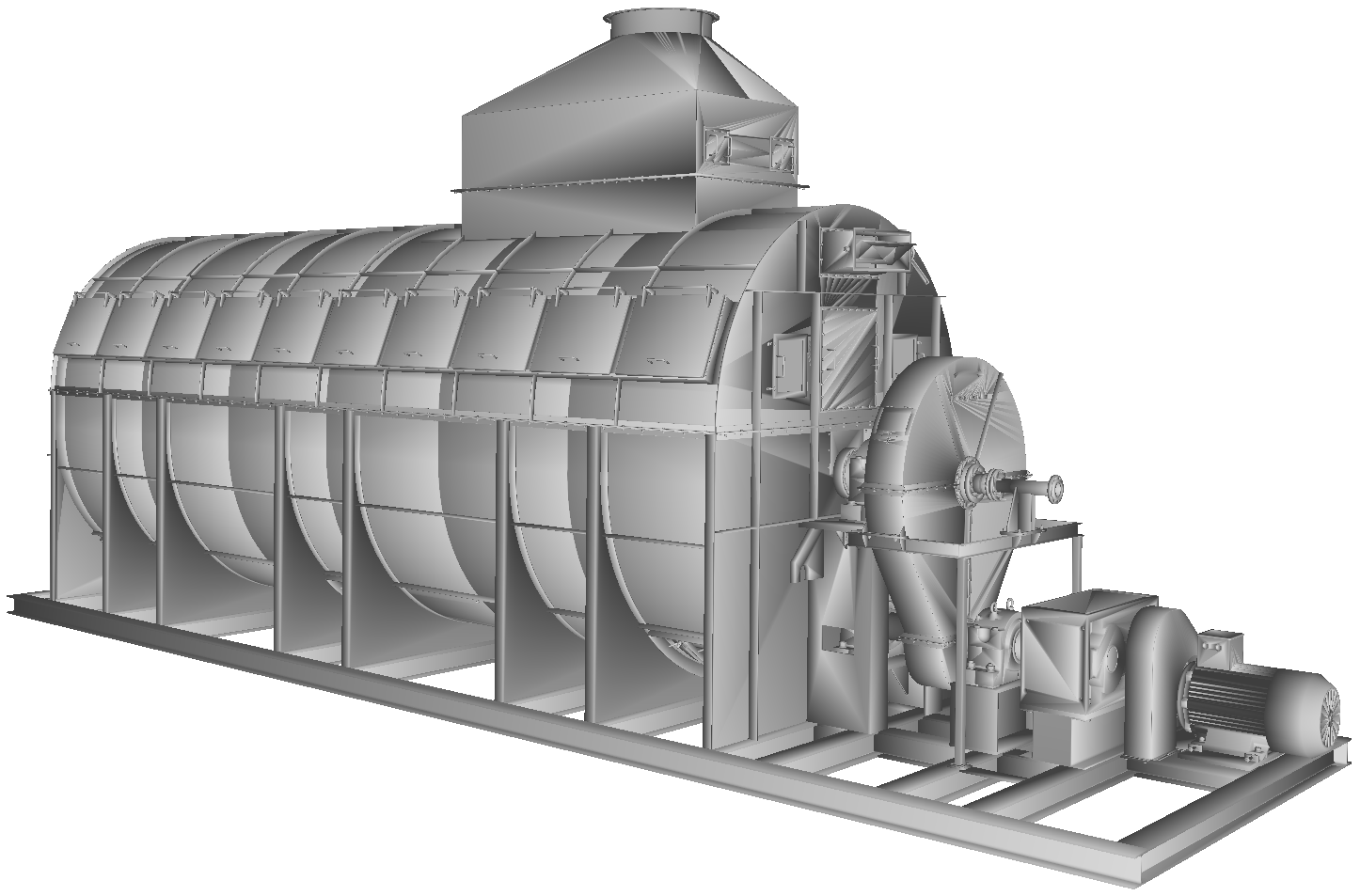

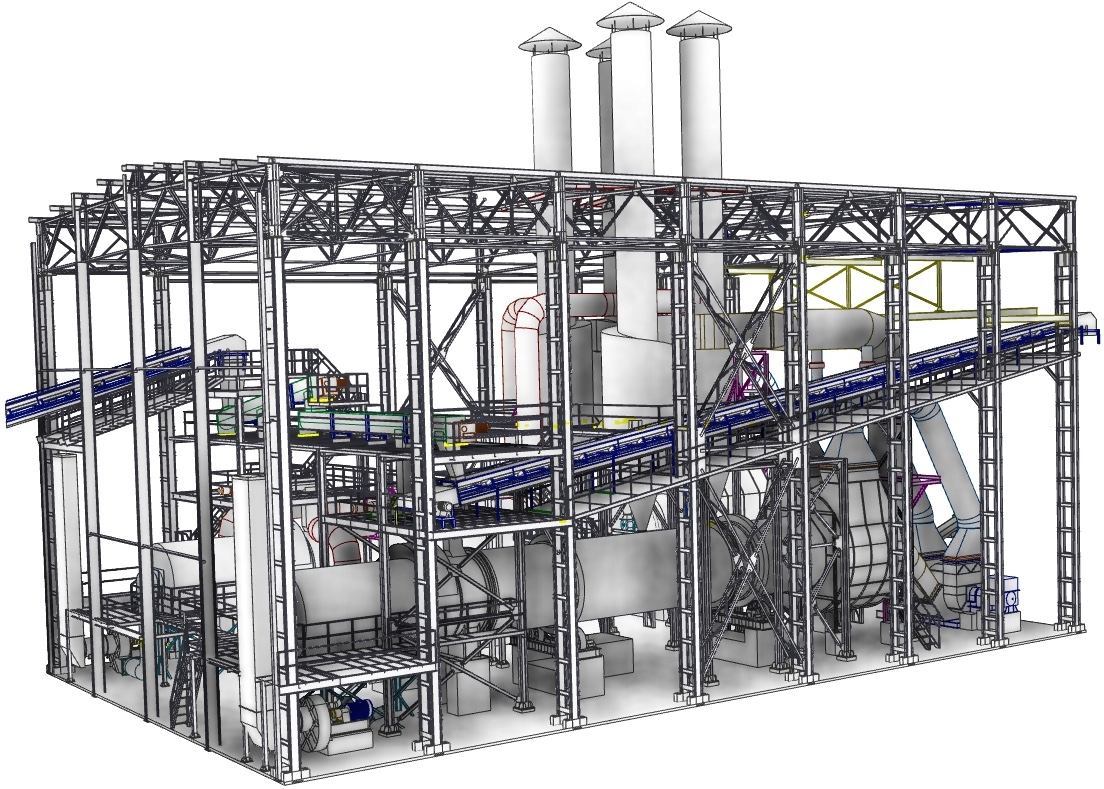

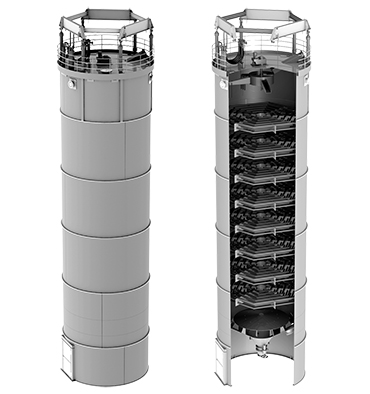

Designed for continuous vertical movement of wet sugar in buckets fixed at a certain pitch on traction chains.

Design features

The ability to vary the elevator’s productivity (can be installed at plants with a productivity of up to 9,000 tons of sugar per day).

The ability to increase the height of the elevator by increasing the body and lengthening the chains.

Stainless steel lining inner surface of the housing and buckets.

Acceleration of installation due to modular design.

Quality

Significant reduction in the amount of ferroalloys in sugar due to successful selection of the material of the elevator surfaces in contact with the product.

Reduction of sugar spillage due to minimizing the gaps between the buckets and the loading and unloading openings.

Reliability

Uninterrupted operation throughout the production season.

Simplified routine maintenance due to removable chains and buckets.

Full access to all moving mechanisms through hatches in the housing.

Simple and reliable in operation moving mechanisms.

Moving and rolling units from leading world manufacturers.

Characteristics

|

Sugar productivity, t/day |

1,140 |

|

Traction chain speed, m/s |

1.25 |

|

Installed capacity, kW |

15 |

|

Power supply, V, Hz |

380/600, 50 |

|

Bucket volume, m³ |

0.014 ÷ 0.02 |

|

Bucket installation pitch, mm |

504 |

|

Bucket material |

stainless steel |

|

Stone mine lining |

stainless steel sheet steel |

|

Weight, kg |

≤ 6,000 |

|

Weight when filled, kg |

≤ 6,600 |

|

Shaft cross-section, mm |

940 x 1,080 |

|

Dimensions – length, mm |

1 795 |

|

Dimensions – width, mm |

3,060 |

|

Dimensions – height, mm |

13 195 |