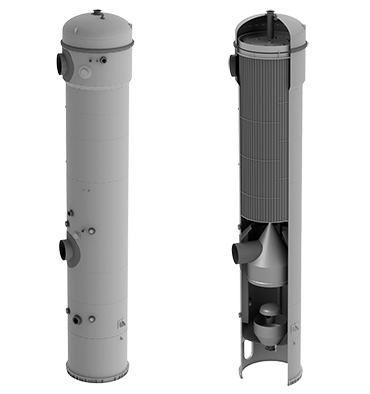

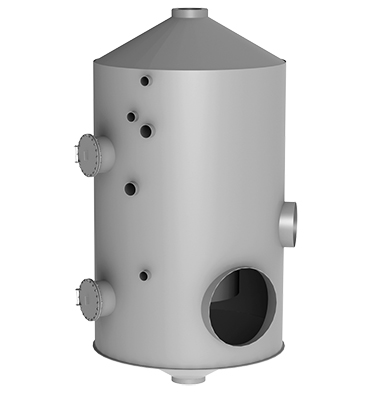

Cartridge-type filter TC-FPI

Cartridge-type filter TC-FPI

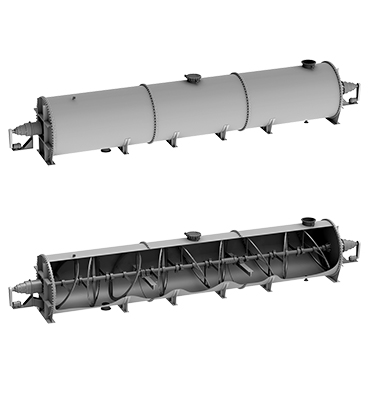

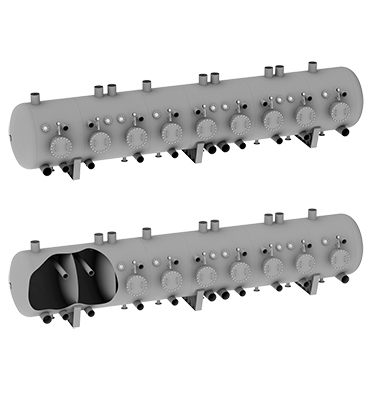

Designed for filtering first and second carbonation juices in beet sugar production, saturated liquor in raw sugar refining, and concentrated syrup.

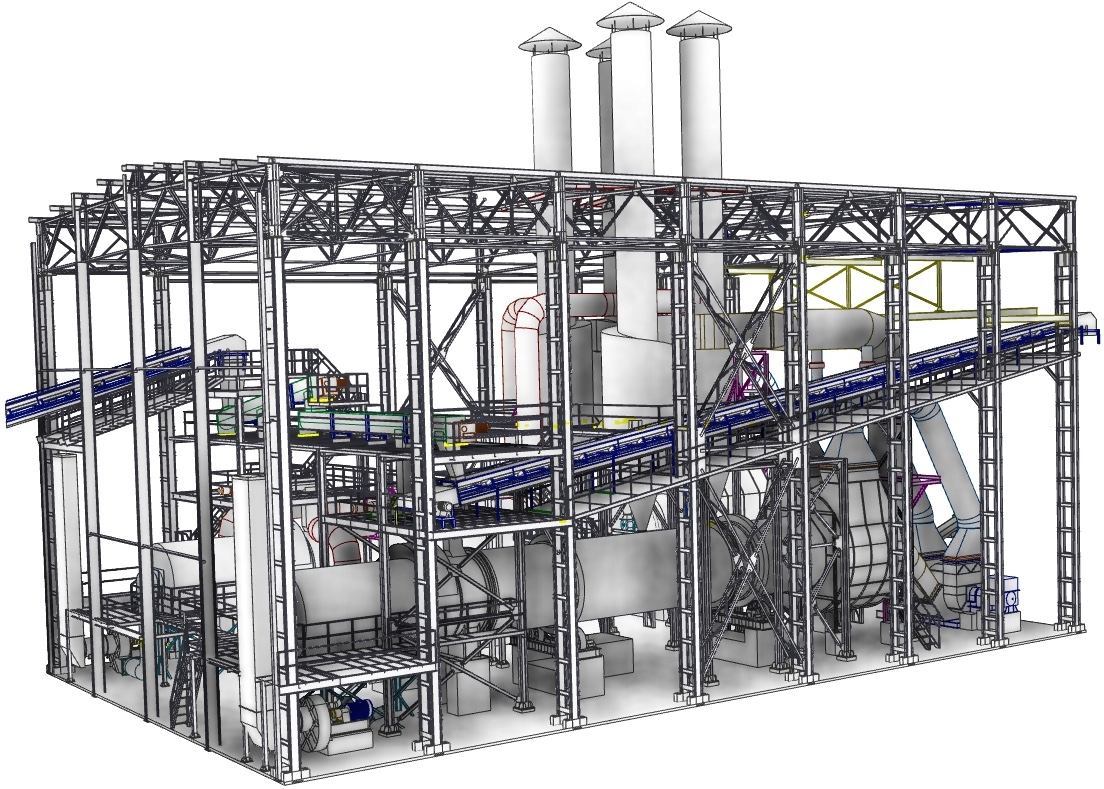

Due to its universal design and ability to work with a wide range of suspensions, the filter can also be used in other industries:

- in the food industry – for the purification of juices, beverages, extracts, broths, and concentrates;

- in the chemical industry – for fine purification of process solutions, acids, alkalis, and salts;

- in the pharmaceutical and biotechnological fields – for filtration of media requiring high purification quality;

- in energy and environmental sectors – for water treatment, wastewater purification, and recirculation flows.

Structual features

Compact construction and larger filtration surface compared to analogues.

Quality

- High filtrate quality;

- High specific capacity due to:

- Full automation of the filtration process;

- Simultaneous filtration and slurry discharge;

- Fast and effective cloth regeneration;

- Obtaining a wide range of specified solid-phase concentrations in the thickened slurry;

- Stable cloth permeability throughout the season thanks to efficient pulse regeneration.

Reliability

Full automation of the filtration process.

Efficiency

Low heat losses due to tight sealing, compact design, and small recirculation volume.

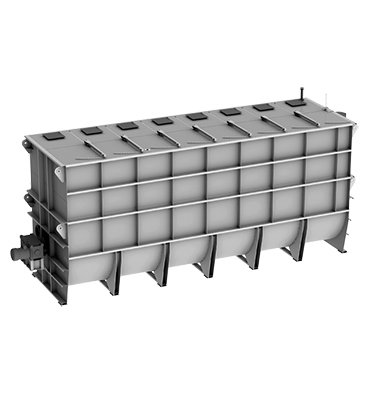

Specifications

| Name | TC-FPI-2000-120 | TC-FPI-2000-138 | TC-FPI-2200-145 | TC-FPI-2200-174 | TC-FPI-2400-175 |

| Specific capacity, m³/m²/hour | |||||

| — for І saturation juice | 0,8–1,0 | ||||

| — for ІІ saturation juice | 1,0–1,2 | ||||

| Filtration surface, m² | 120 | 138 | 145 | 174 | 175 |

| Maximal pressure, bar | 6 | ||||

| Overall dimensions, mm: | |||||

| Length | 3 400 | 3 400 | 3 500 | 3 500 | 2 680 |

| Width | 2 600 | 2 600 | 2 800 | 2 800 | 2 980 |

| Height | 7 100 | 7 100 | 7 200 | 7 200 | 7 550 |

| Mass, kg | 4 800 | 5 000 | 6 200 | 6 500 | 9 000 |