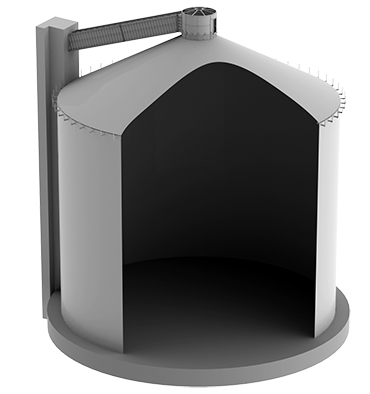

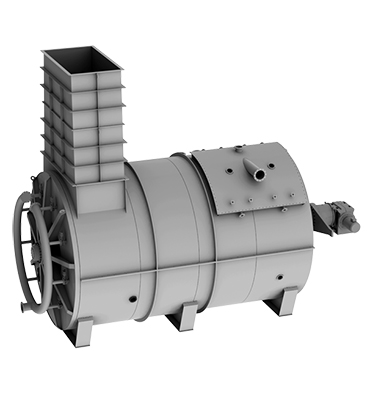

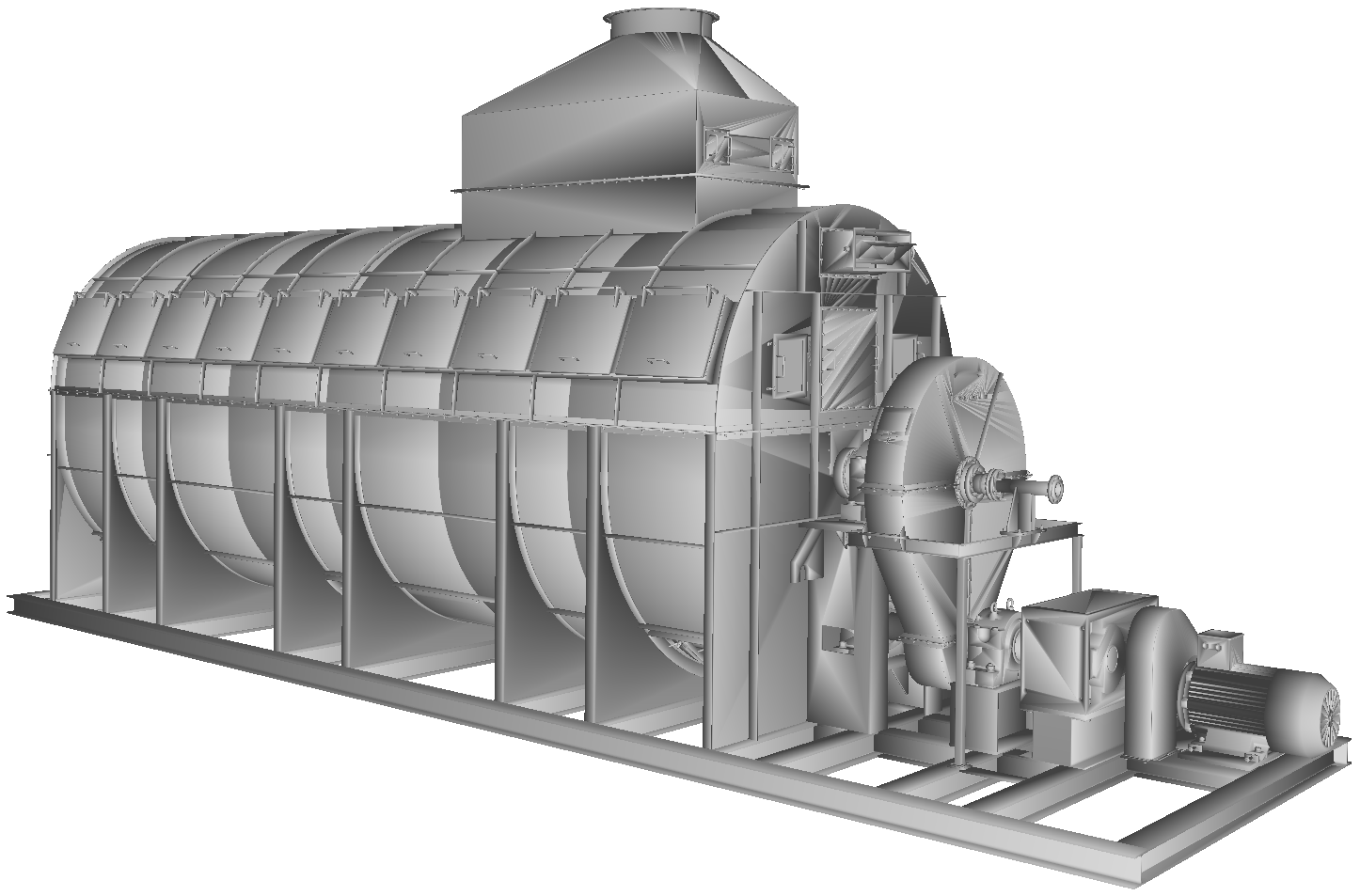

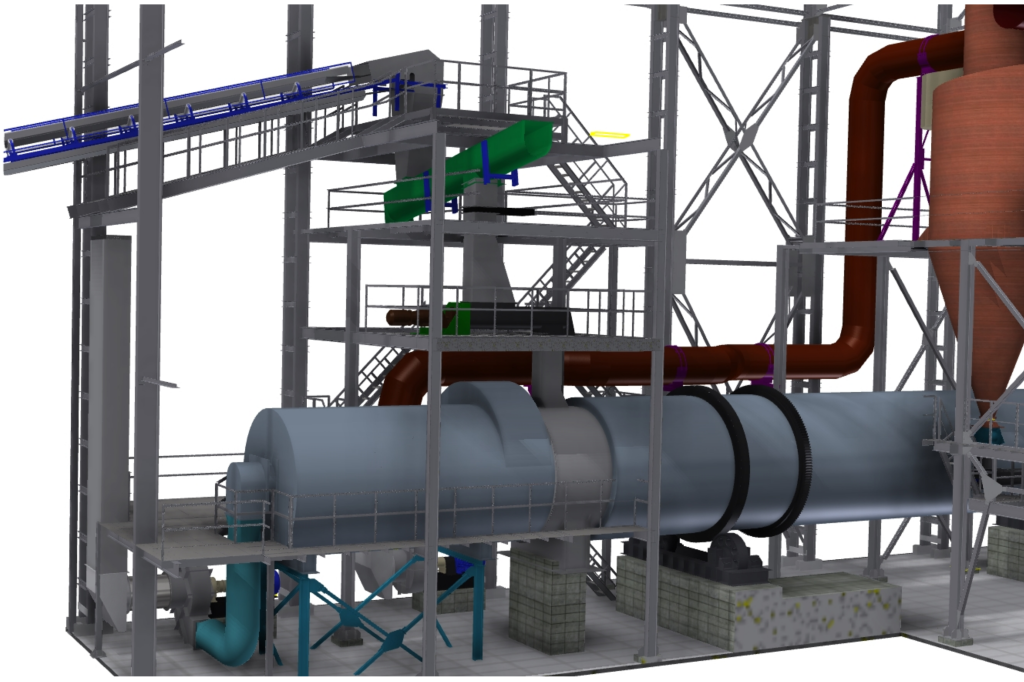

Furnace chamber TC-FN

Furnace chamber TC-FN

Designed for natural gas combustion, producing a drying agent for efficient drying of beet pulp and various raw materials.

Structual features

- Optimal mixing of gas and air before the combustion zone ensures a stable process;

- Maximum fuel efficiency with minimal CO and NOx emissions in the exhaust;

- Stable flame conditions thanks to a unique system of air flow distribution;

- Flexible application — supports the use of multiple burner types;

- Maximum efficiency — less fuel, lower costs;

- Designed to allow the use of waste flue gases.

Quality

- Operational stability — steady combustion and reliable functioning at all times;

- High eco-efficiency — very low emissions of harmful compounds in flue gases;

- Long-lasting materials — heat-resistant steel construction ensures durability under high temperatures;

- Reliable operation — minimal downtime and long-lasting performance;

- Comprehensive quality control throughout the entire manufacturing process.

Automation

- Complete control of the process — automated systems provide precise regulation of gas and air supply;

- Operational stability — automated sensors ensure optimal combustion conditions;

- Safe operation — automated system reacts instantly to anomalies, avoiding failures;

- Ease of use — intuitive interface with minimal training required;

- Flexibility — can be integrated into the overall plant control system.

Specifications

| Name | TC-FN-180 | TC-FN-200 | TC-FN-260 |

| Type of fuel | Natural gas | ||

| Gas consumption capacity, m³/h | 1 500 – 1 800 | 2 000 | 4 000 |

| Combustion air flow rate, m³/h | 17 000 | 23 000 | 36 000 |

| Temperature at the outlet of the combustion chamber, °C | 950 | ||

| Negative pressure in the combustion chamber, Pa | -50 | ||

| Overall dimensions, mm: | |||

| Diameter of furnace | 3 000 | 3 400 | 4 000 |

| Length | 6 896 | 6 640 | 8 400 |

| Width | 3 400 | 4 267 | 5 070 |

| Height | 3 548 | 4 000 | 4 600 |

| Mass, kg | 12 700 | 13 000 | 21 000 |