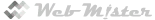

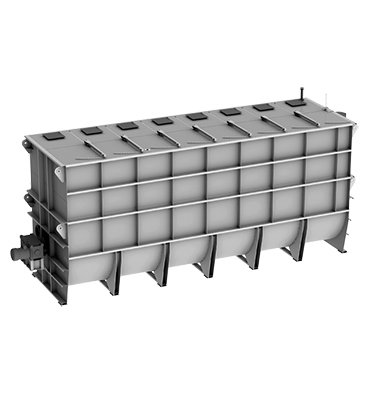

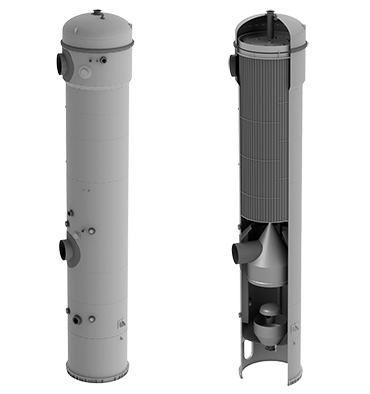

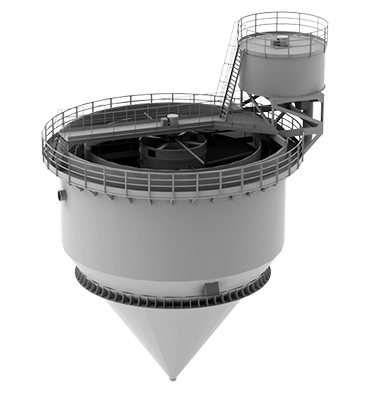

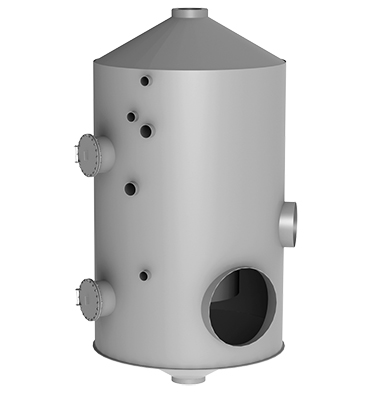

Barometric Condenser TC-KUP

Barometric Condenser TC-KUP

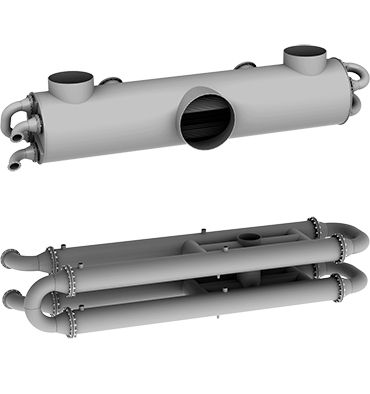

Designed for condensing process steam from evaporation, distillation, and other thermal systems, as well as for creating the required vacuum to maintain optimal temperature conditions during operation;

Used in installations within the food, chemical, pharmaceutical, and related industries.

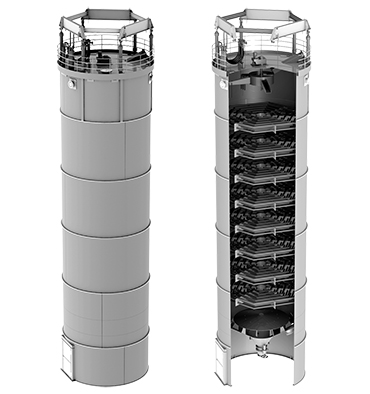

Structural features

- Developed jet-cascade water distribution system;

- Low sensitivity to scale formation on internal surfaces; simple and reliable design suitable for deep vacuum

- operation;

- Low hydraulic resistance;

- Stable operation across a wide range of steam flow rates;

- Easy installation without the need for complex mounting components;

- Option for additional configuration with an external separator to remove water from non-condensable gases.

Quality

- Provides stable vacuum required for efficient evaporation or condensation processes;

- High heat exchange efficiency with minimal cooling water consumption;

- Wide operating range in terms of steam and coolant flow rates.

Efficiency

- Minimal temperature difference between condensing steam and heated water — reducing water consumption;

- Low energy costs for water circulation;

- Reduced load on vacuum pumps due to cooling of non-condensable gases;

- Maximum use of heated water for technological needs (e.g., heating of liquids or solutions);

- Ability to operate using recirculated water without additional technical water supply;

- Fuel savings achieved through optimization of thermal processes.

Reliability

- Stable operation throughout the production cycle, even with scale deposits on heat exchange surfaces;

- Consistent vacuum performance under variable process loads and changing product quality.

Automation

- Fully automated process control with minimal operator intervention;

- Flexible parameter adjustment for different product types and operating conditions;

- Integrated system for monitoring temperature, vacuum, and water flow;

- Instant response to changes — sensors and automation maintain stable operating conditions without interruptions;

- User-friendly interface — easy to learn and provides quick access to all functions.

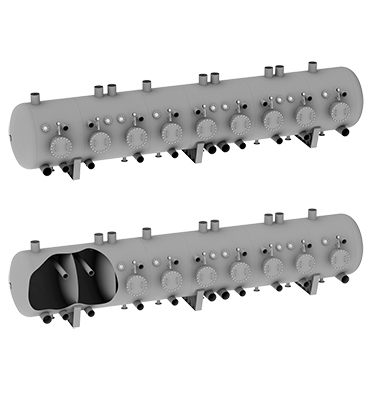

Specifications

| Name | TC-KUP-15 | TC-KUP-30 | TC-KUP-45 | TC-KUP-60 | TC-KUP-75 | TC-KUP-90 |

| Steam consumption, t/hour | 15 | 30 | 45 | 60 | 75 | 90 |

| Hydraulic resistance, Pa, not more | 50 | |||||

| Nominal vacuum up to, bar | -0,9 | |||||

| Underheating of return water to saturation temperature, °C |

3 – 5 |

|||||