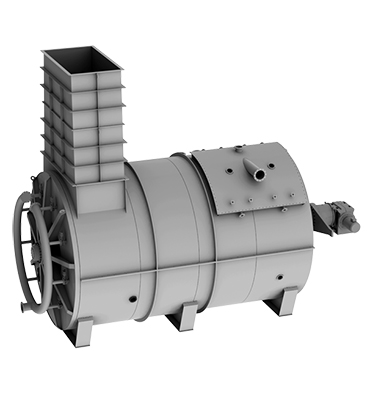

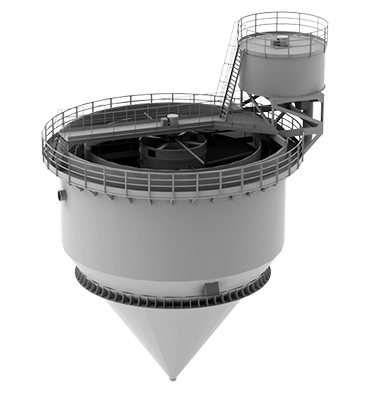

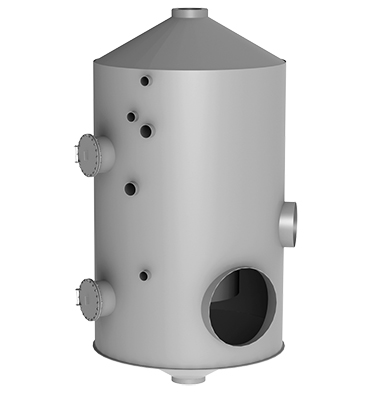

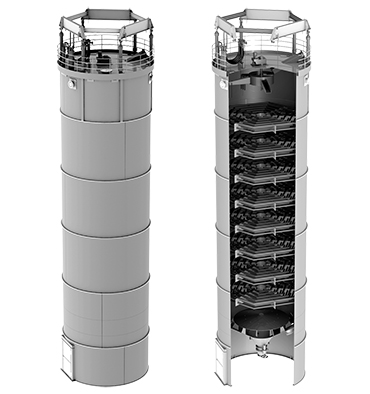

Vertical crystallizer with a moving surface TC-VК

Vertical crystallizer with a moving surface TC-VК

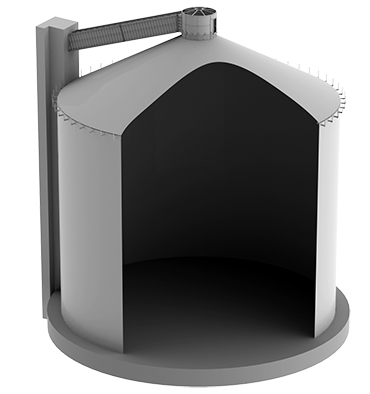

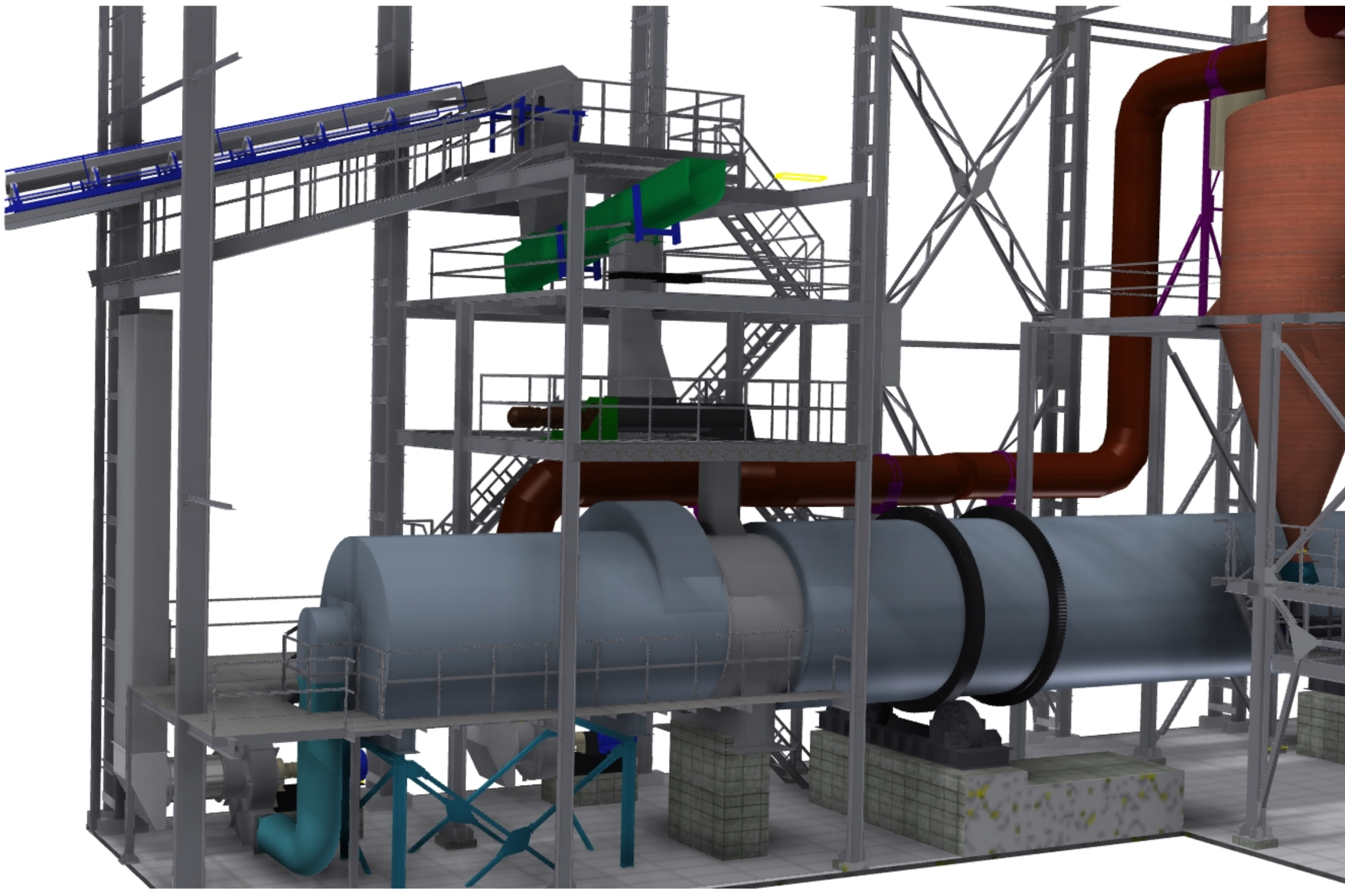

Designed for additional crystallization of sugar by cooling the mass of the final product. The device is installed outside the main building on a small open area.

Design features

Ensuring a uniform cooling process by regulating the temperature difference between the massecuite and the cooling water.

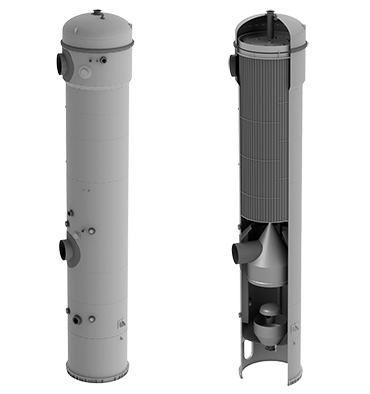

Providing a self-cleaning effect due to the reciprocating motion of the cooling surface.

Ability to work with high-viscosity massecuite.

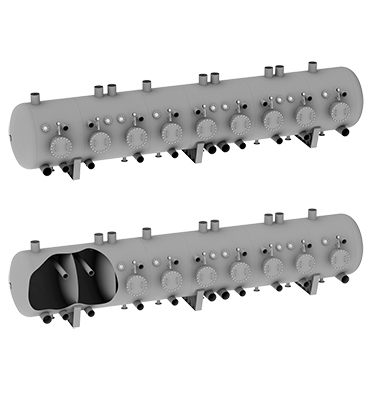

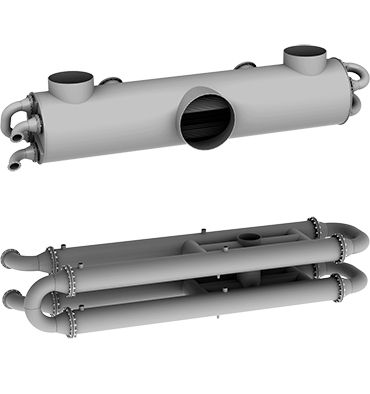

Presence of two independent contours of the heat exchange surface.

Quality

Uniform cooling process.

Easy passage of viscous product.

High crystallization effect.

High technological performance during grouting due to the correct structure crystals.

Economical

Reduced sugar losses in molasses.

Reliability

No rollers and seals on the massecuite side.

Reliable and simple hydraulic cooling surface actuator.

Fully automatic control.

Minimal requirements for maintenance of the device during operation.

Characteristics

|

|

TC VK-350 |

TC VK-450 |

|

Useful volume, m³ |

350 |

450 |

|

Cooling surface area – min., m² |

440 |

640 |

|

Cooling surface area – max. m² |

640 |

840 |

|

Specific cooling surface – min., m²/m³ |

1.26 |

1.40 |

|

Specific cooling surface – max., m²/m³ |

1.83 |

1.87 |

|

Weight, kg |

85,000 |

120,000 |

|

Dimensions – height of the cylindrical part, mm |

22,300 |

28,000 |

|

Dimensions – outer diameter, mm |

5,200 |