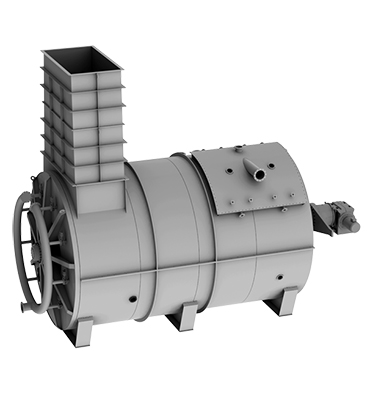

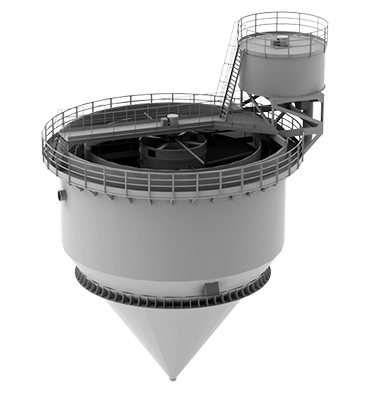

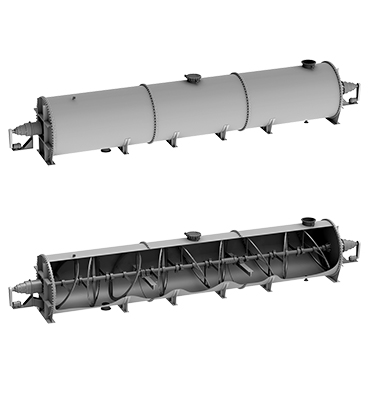

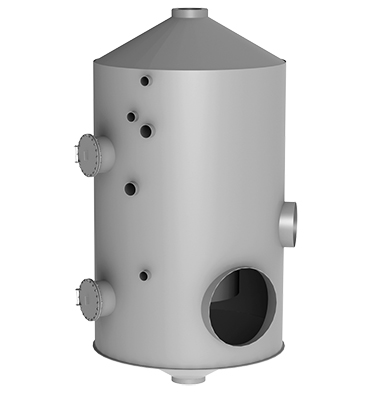

Seed magma pressure mixer TC-MHK

Seed magma pressure mixer TC-MHK

Designed for accumulation and mixing of master masseuse before feeding it into the apparatus.

The pressure mixer is equipment of the two-stage masseuse boiling scheme and an integral part of the masseuse A (B and C) cooking scheme of products based on master masseuse.

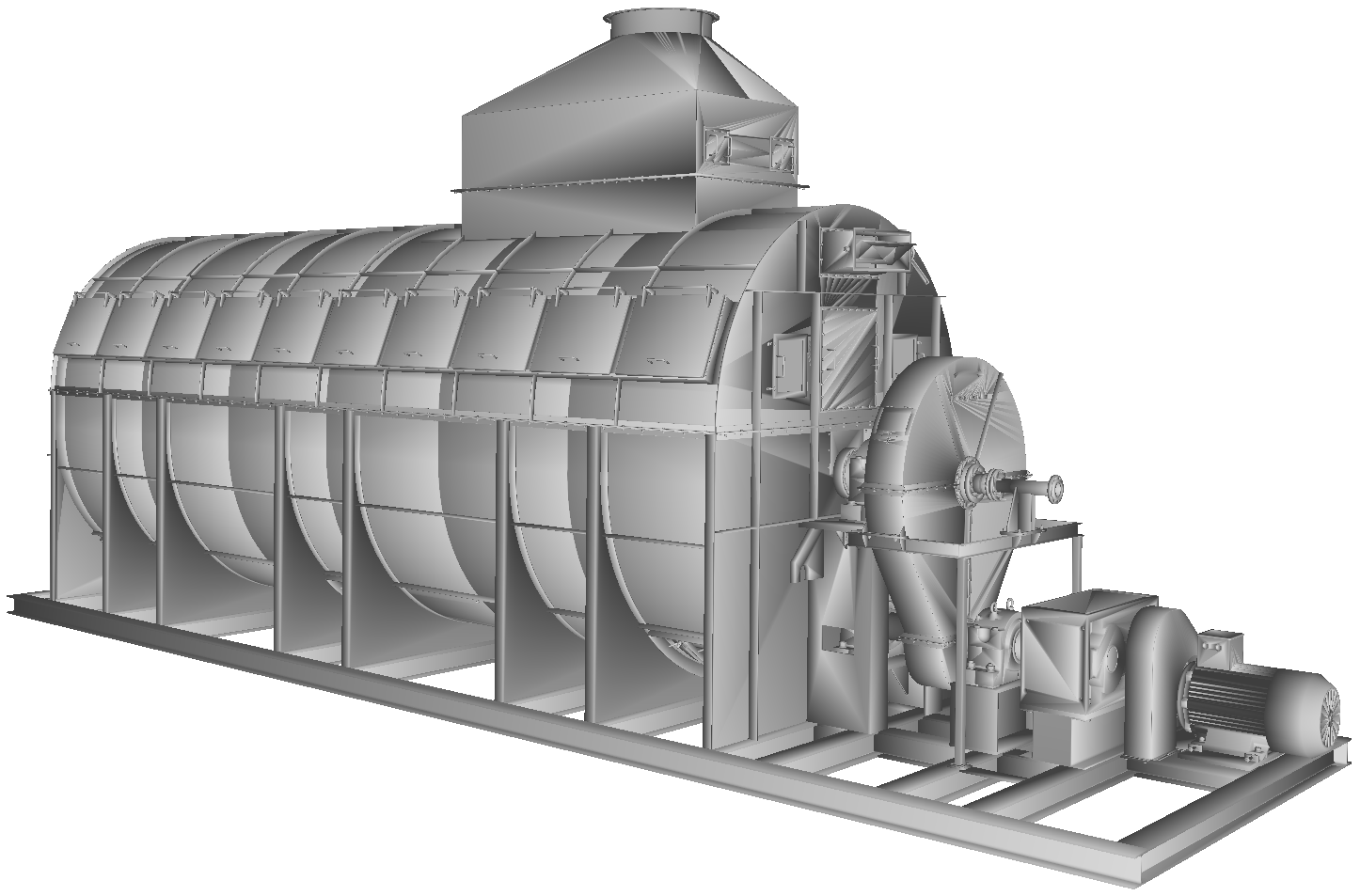

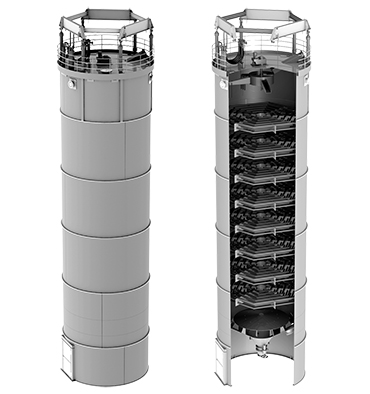

Design features

The ability to adjust the shaft rotation speed.

Providing a casing to maintain the temperature of the master masseuse massefels.

Quality

Preservation of the crystal structure of the massefels.

Optimal mixing of the massefels.

Economics

Reduction of cooking time of massefels A (B and C) products.

Reduction of sucrose losses.

Reduction of water consumption for bleaching sugar of the A product and when grouting massefels B and C products.

Reduction of steam consumption in the food compartment.

Minimum maintenance requirements.

Reliability

Prevention of sugar encrustation on the walls of the mixer due to the quality of the internal processing? surface (polished stainless steel).

Presence of an emergency scrolling system for the mixing device.

Characteristics

|

Useful volume, m³ |

15 |

|

Installed power of the electric motor, kW |

4 |

|

Shaft speed adjustment range, rpm. |

0.6-3.2 |

|

Material in contact with product |

12Х18Н10Т |

|

Weight, kg |

4 700 |

|

Dimensions – length, mm |

5 700 |

|

Dimensions – width, mm |

2 900 |

|

Dimensions – height, mm |

2 900 |