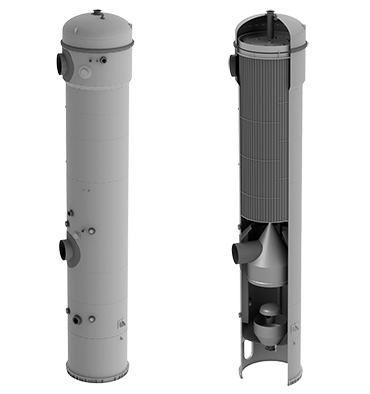

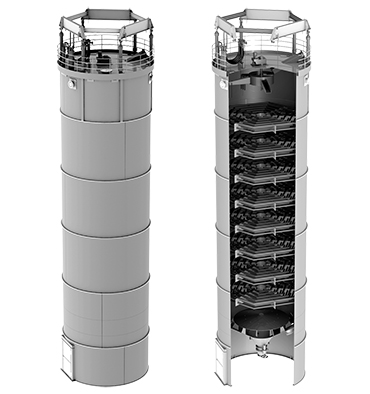

Sugar Cooler TC-SC

Sugar Cooler TC-SC

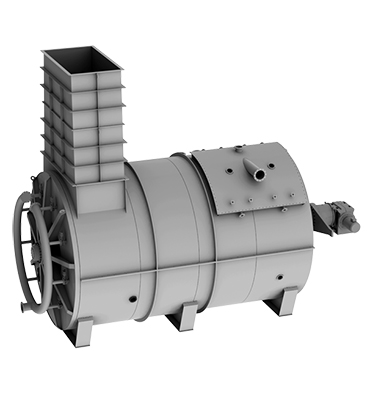

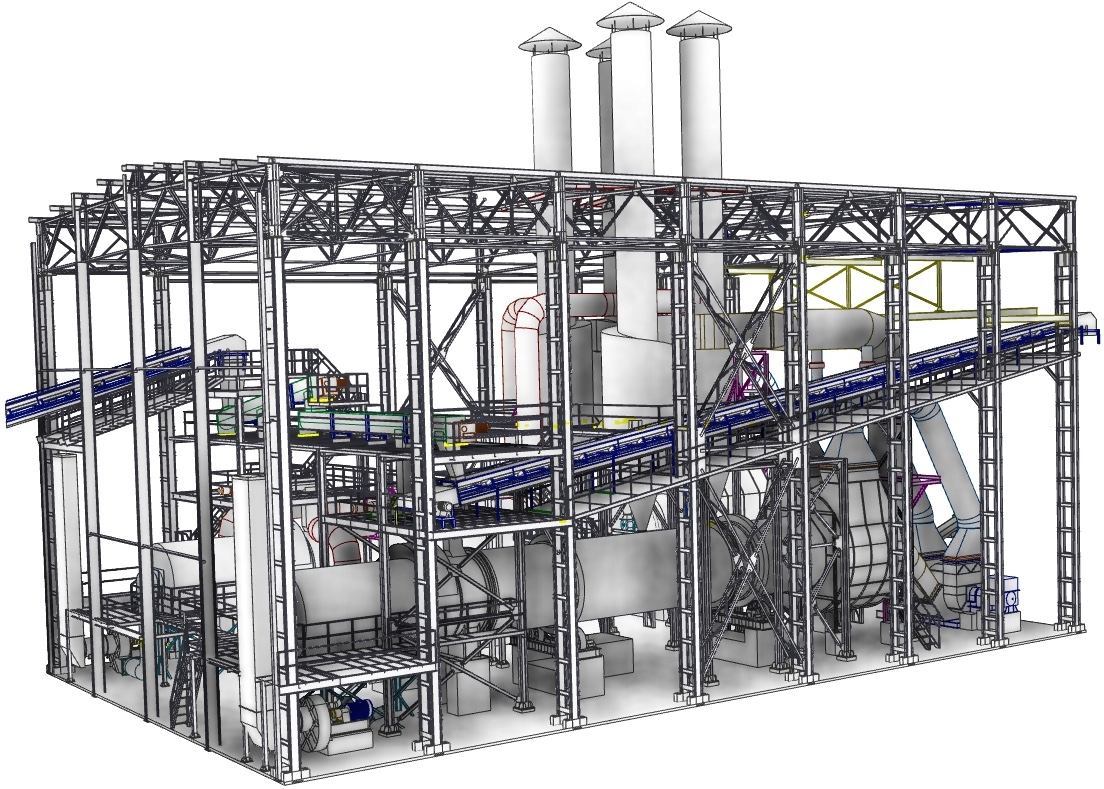

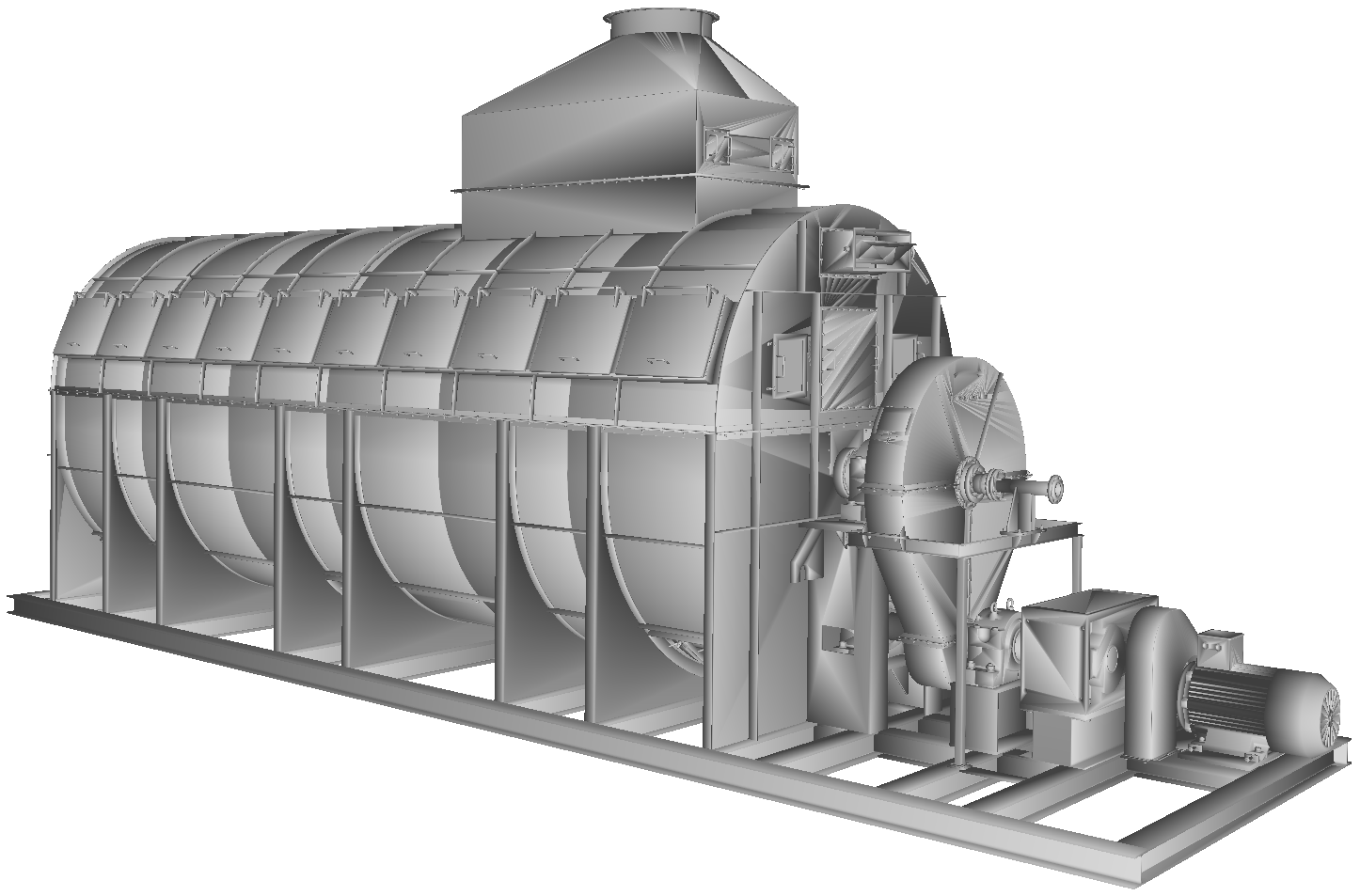

Designed for cooling sugar after the drying unit by direct contact with the heat exchange surface. Used in the processing of sugar beets and raw sugar at sugar industry enterprises. Typically, water is used as a cooling agent, which is supplied from a closed circuit of the cooler or from an open source of chilled water.

Design features

Combination of the principle of bulk material mass flow with plate heat exchanger technology.

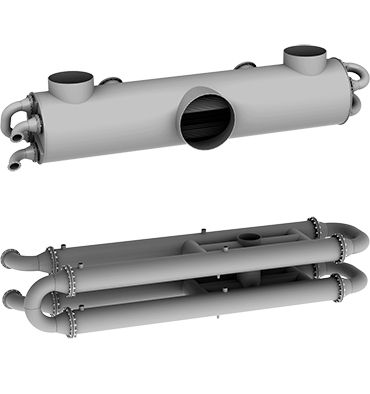

Organization of the movement of bulk product along the outer surface of the plates from top to bottom and circulation of the cooling liquid (water/glycol), which cools the sugar to the required temperature, along the inner surface.

The possibility of further expansion of the structure to increase its productivity due to the multi-block nature of the apparatus.

Easy installation of the apparatus both in the case of modernization of existing production and in the construction of a new one.

Quality

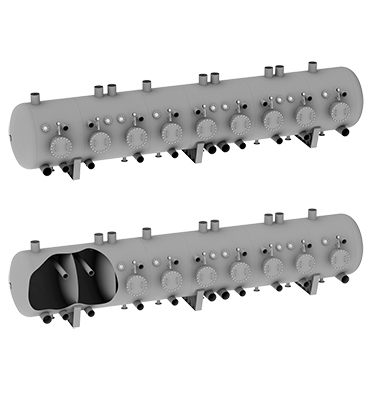

Special design of the unloading hopper, which is installed on hangers and equipped with a vibratory motor for product mass flow.

Soft processing of the product, which avoids the destruction of sugar crystals.

Economical

Increased heat exchange area due to the vertical arrangement of the device.

Reduction of heat energy losses in contrast to devices based on fluidized bed and drum-type devices.

Reliability

A small number of moving parts of the device.

Reliable regulation of the sugar feed rate using a vibratory actuator of the unloading hopper, which allows you to quickly change the device’s performance and the temperature of the cooled sugar.

Automation

Automatic change of the device’s performance and the degree of sugar cooling.

Setting of the periodic operating mode by means of controlling the upper and lower levels of the device.

Characteristics

|

Productivity, t/day |

600 – 1,200 |

|

Number of heat exchange elements, pcs. |

41 – 82 |

|

Total heat exchange surface area, m2 |

244 – 488 |

|

Working pressure, bar |

3 |

|

Material of elements in contact with sugar |

08Х18Н10 |

|

Material of elements not in contact with sugar |

03Х16Н15М3 |

|

Driver power, kW |

2 x 0.9 |

|

Weight, kg |

4,400 – 8,700 |

|

Dimensions — length, mm |

2,025 |

|

Dimensions — width, mm |

2,070 |

|

Dimensions — height, mm |

5,410 – 8,170 |