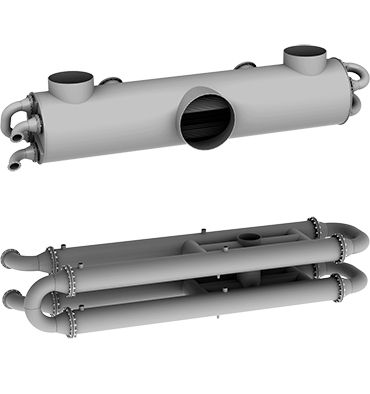

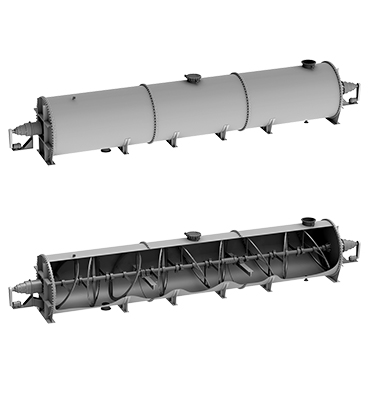

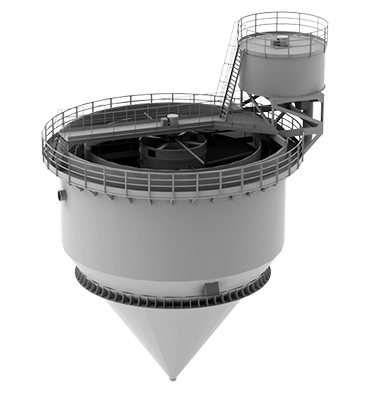

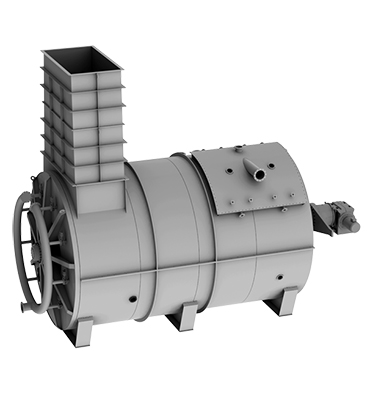

Shavings scalder for TC-OS diffusion devices

Shavings scalder for TC-OS diffusion devices

Designed for scalding beet shavings – the initial stage of the sugar extraction process, when the shavings are heated by countercurrent heat exchange with diffusion juice. It is used as part of diffusion units of various types and can be used to retrofit existing diffusion departments of sugar factories.

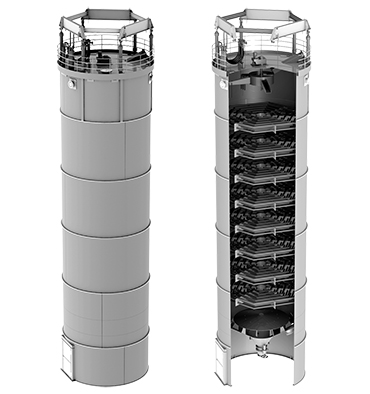

Design features

Compact single-shaft design with a simple and reliable transport and mixing system.

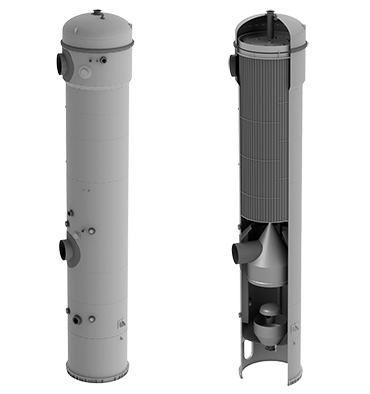

Grid screens with double-conical slots.

Quality

Impossibility of oxidation and foaming due to the lack of contact of the juice-chip mixture with air.

Removal of gas bubbles from the juice-chip mixture mixture.

Slight chip crushing during the scalding process.

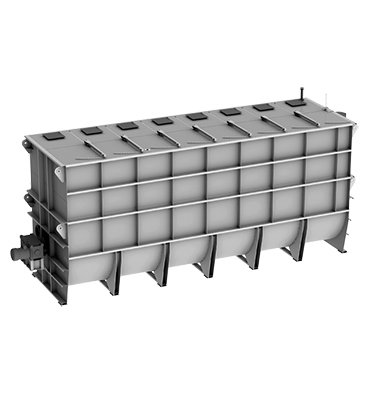

Reliability

Three-stage protection of the motor against overload.

Corrosion-resistant surfaces in contact with the product.

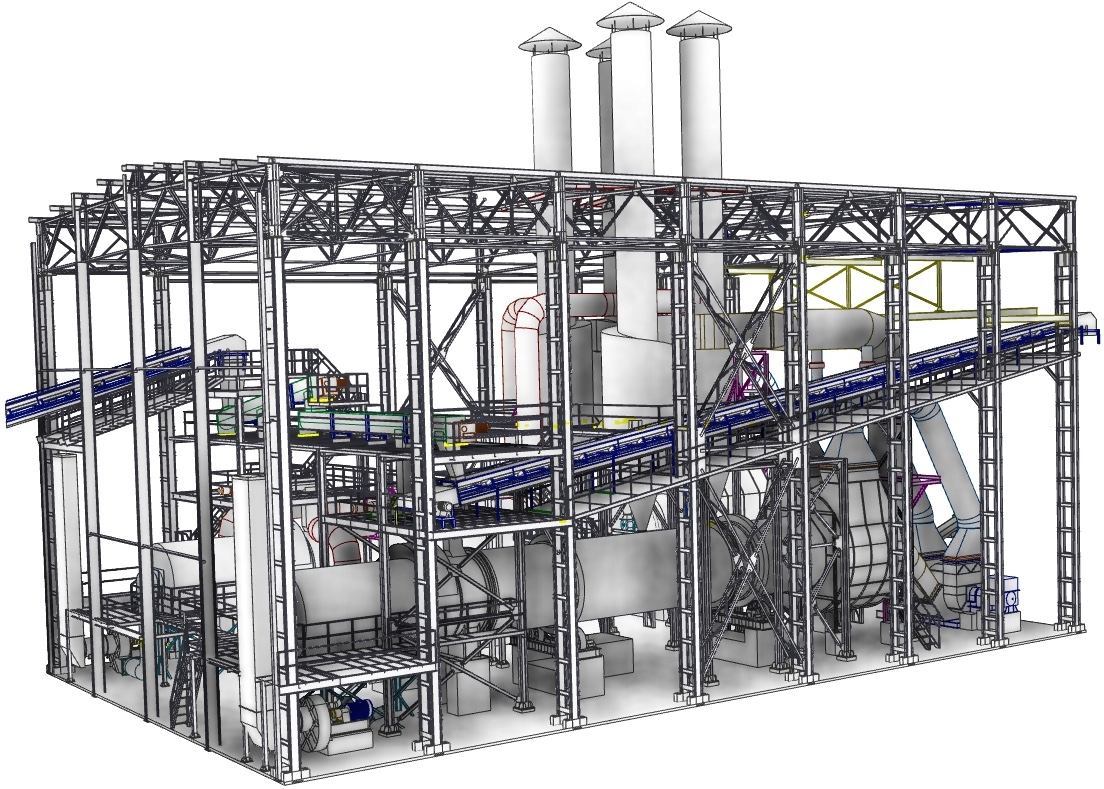

Economical

Possibility of using low-potential heat to heat the diffusion juice.

Maximum use of the internal volume during the scalding process.

Automation

Maintaining optimal? density of filling of the working volume with chips.

Automatic adaptation of the mode when changing the quality of the chips.

Stabilization of the temperature regime of the scalding process.

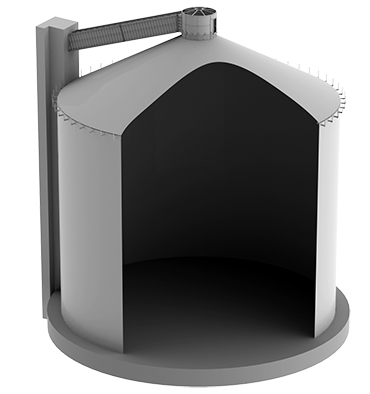

Characteristics

|

Beet productivity, t/day |

6,000 |

|

Installed capacity, kW |

45 |

|

Power supply, V, Hz |

380/600, 50 |

|

Shaft rotation frequency, rpm. |

0.4-1.4 |

|

Inner diameter of the housing, mm |

5,200 |

|

Outer diameter of the pipe, mm |

2,000 |

|

Weight, kg |

≤ 60,100 |

|

Dimensions – length, mm |

9 108 |

|

Dimensions – width, mm |

5 464 |

|

Dimensions – height, mm |

11,795 |