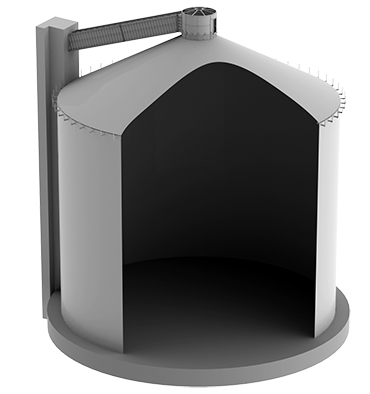

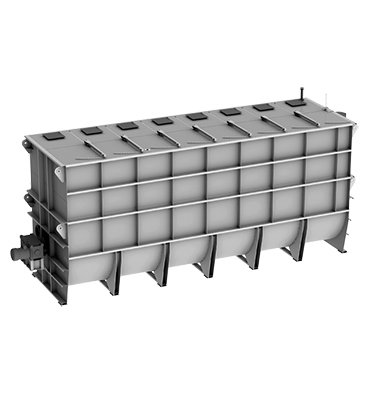

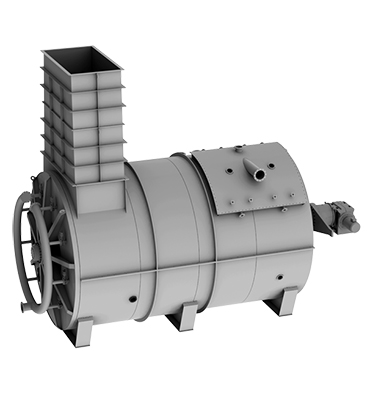

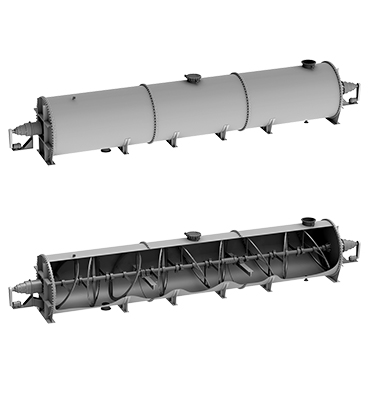

Receiving mixer for master batch TC-ММU

Receiving mixer for master batch TC-ММU

Designed for receiving cooked master batch. It is an integral part of the massecuite cooking scheme for A (B and C) products based on master massecuite and works as a buffer vessel in the master massecuite dosing circuit for A (B and C) vacuum devices for products.

Design features

Wider options for choosing a location due to the prefabricated design compared to other integral mixers of the same volume.

Protection against corrosion of the upper part of the mixer (at the customer’s request, the receiving mixer can be made entirely of stainless steel).

Optimal mixing of massecuite.

Prevention of the formation of stagnant zones.

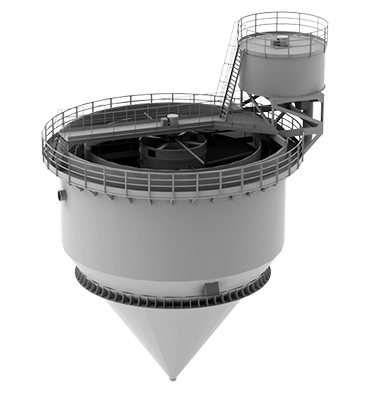

Economic efficiency

Reduction of massecuite cooking time for A (B and C) products.

Reduction of water consumption when grouting massefies.

Reduction of steam consumption in the food department.

Reduction of sucrose losses.

Improvement of the crystal structure of massefies.

Reliability

Minimum maintenance requirements.

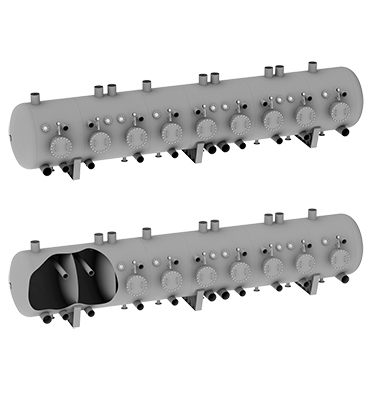

Characteristics

|

Useful volume, m³ |

49 |

|

Electric motor power, kW |

2 x 5.5 |

|

Body diameter, mm |

2,370 |

|

Dimensions — length, mm |

15 200 |

|

Dimensions – width, mm |

2,510 |

|

Dimensions – height, mm |

2,760 |