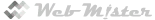

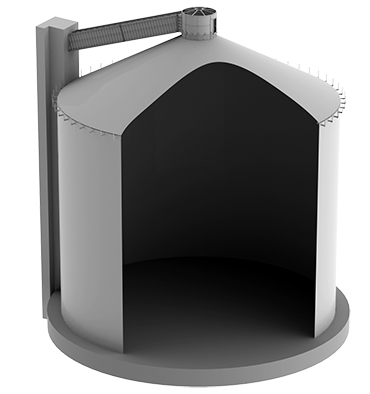

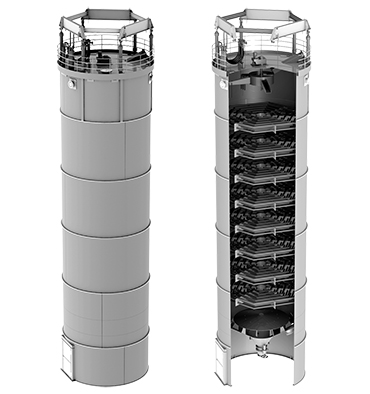

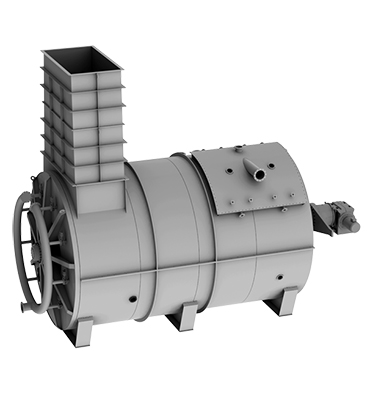

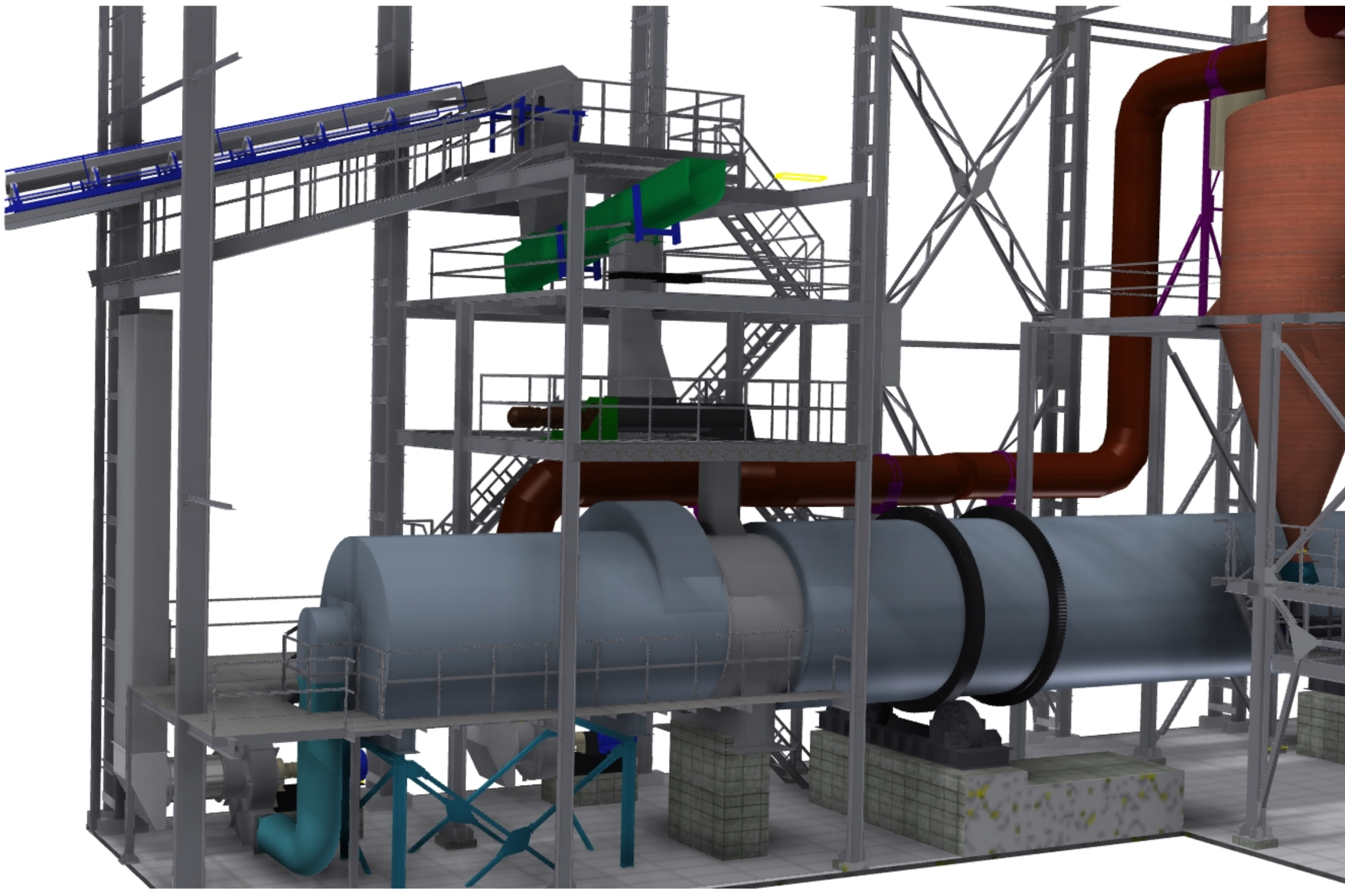

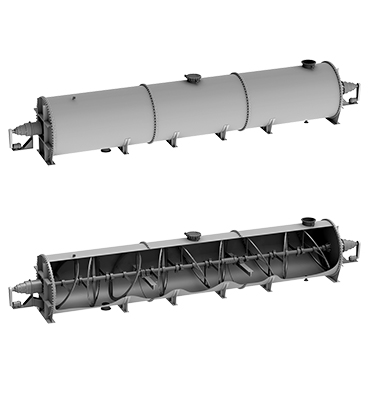

Rotary dryer TC-RDA

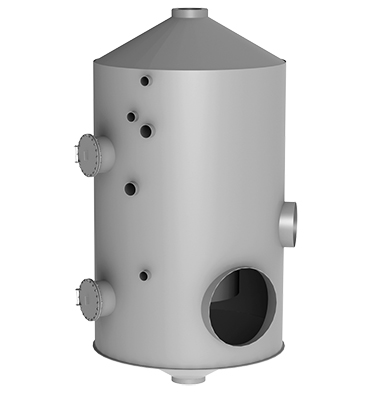

Designed for drying bulk, granular, and small-piece materials through intensive heat and mass transfer between the product and streams of heated or cooled air (or flue gases). It is used for beet pulp, distillers grain (DDGS), grain products, and various food or technical materials.

Structual features

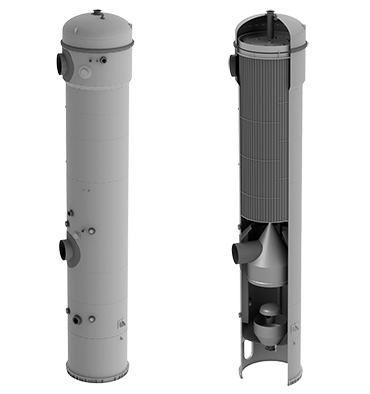

A compact and easy-to-maintain design with a rotating drum equipped with lifters for uniform lifting and mixing of the product;

The possibility of operating in co-current or counter-current flow;

Stable operation without frequent cleaning due to the optimized drum geometry and efficient aspiration system;

Execution in carbon or stainless steel depending on food or industrial requirements.

Quality

Uniform drying, control of final moisture, and stability of process parameters ensure the guaranteed quality of the finished product;

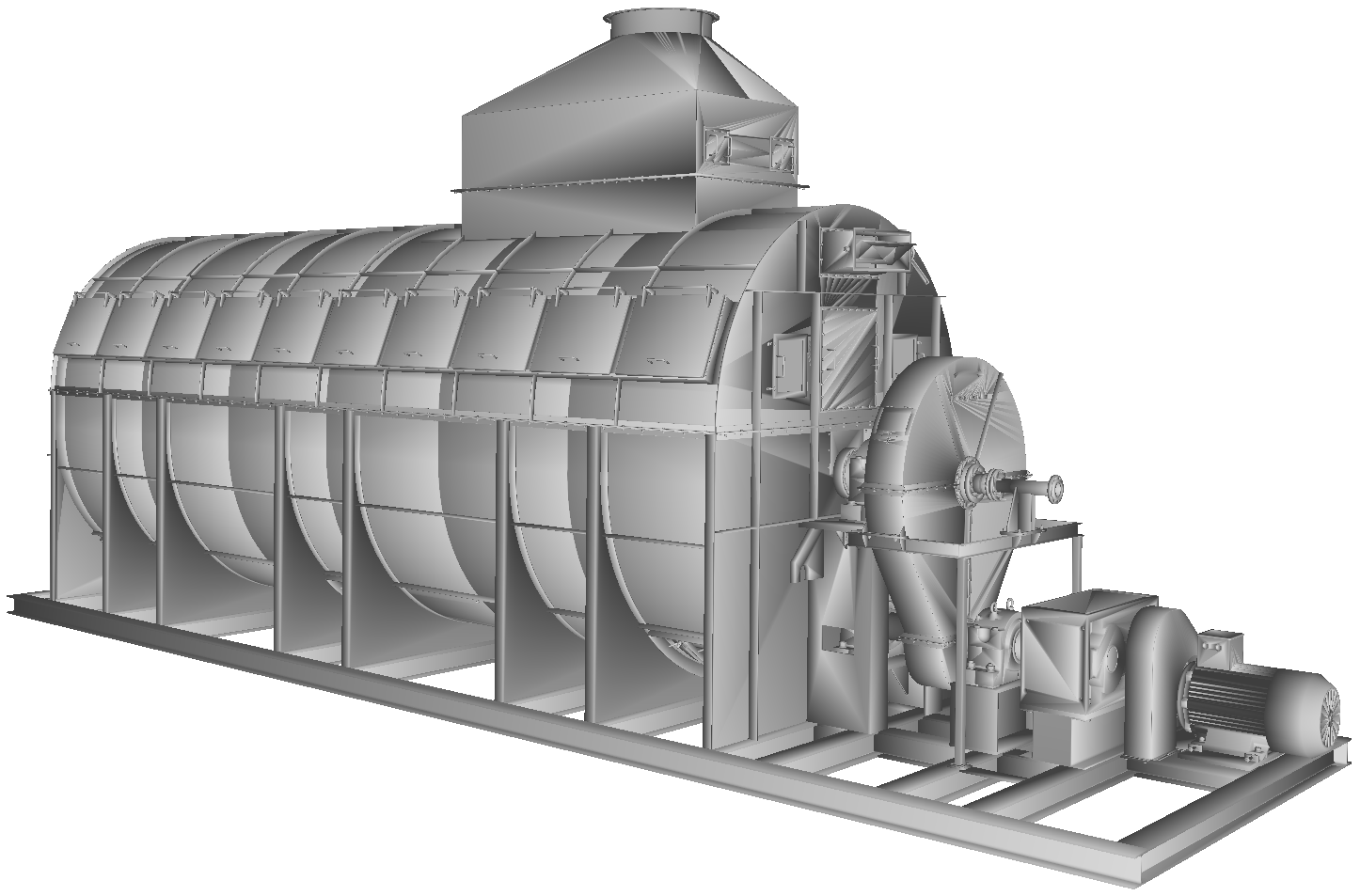

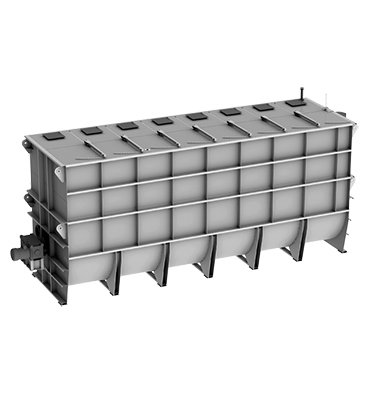

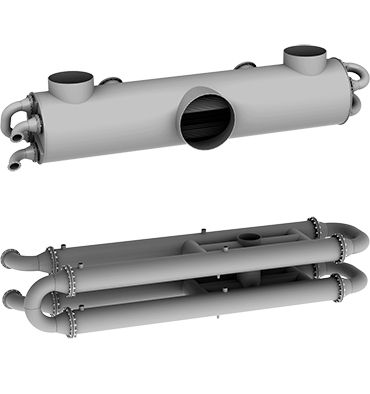

Together with the horizontal cooler TC-SCH-3/TC-SCH-6, it provides a complete cycle of product preparation for bulk storage;

The optimal temperature regime ensures the preservation of structural and nutritional properties of the product.

Automation

The automated control system (ACS/SCADA) provides automatic control of temperature, vacuum, air flow rate, and product moisture;

Operating modes adapt to different types of materials;

Integration with the plant’s SCADA system ensures high safety, monitoring, and logging of all technological parameters.

Specifications

| Name | TC-RDA-25 | TC-RDA-30 | TC-RDA-40 |

| Nominal productivity in drying and cooling mode, t/h | 25 | 30 | 40 |

| Nominal productivity in drying mode, t/h | 35 | 55 | 75 |

| Product humidity, no more, % | 0,04 | ||

| Temperature of dried product, °C | 25 − 30 | ||

| Air temperature for drying, °C | 70 − 100 | ||

| Air temperature for cooling, °C | 17 | ||

| Motor power, kW | 15 | 22 | 30 |

| Overall dimensions, mm: | |||

| Length | 10 660 | 13 170 | 13 860 |

| Width | 2 800 | 3 200 | 3 660 |

| Height | 4 525 | 5 430 | 6 020 |

| Mass, kg | 25 230 | 35 210 | 61 150 |