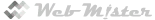

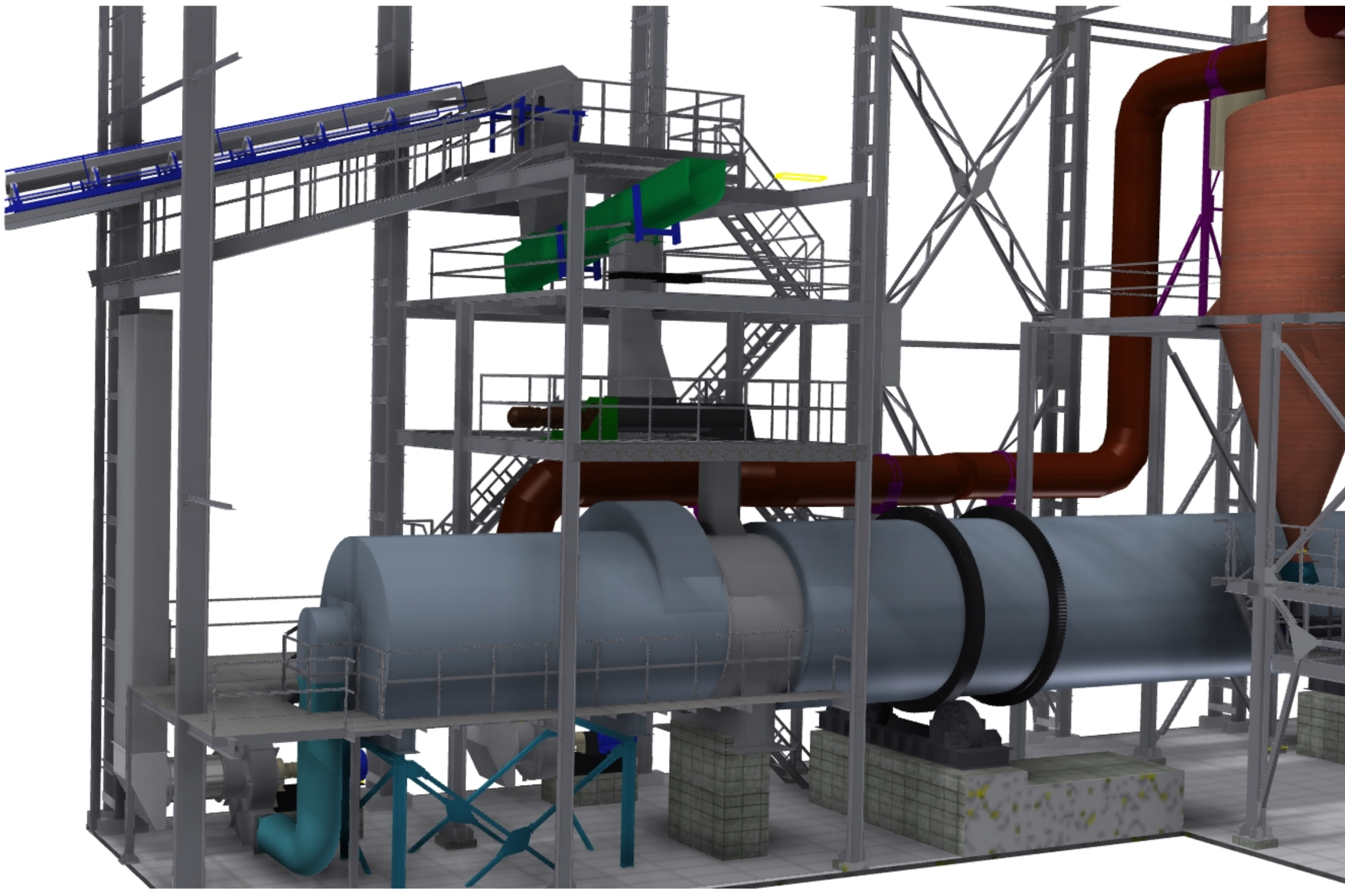

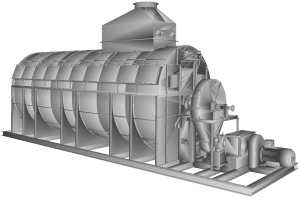

Rotary-tubular drying drum TC-TBD

Rotary-tubular drying drum TC-TBD

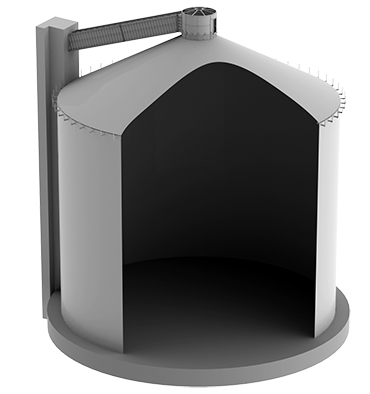

Efficient drying of grain residues from bioethanol production, as well as for use in the feed and brewing industries.

Structural features

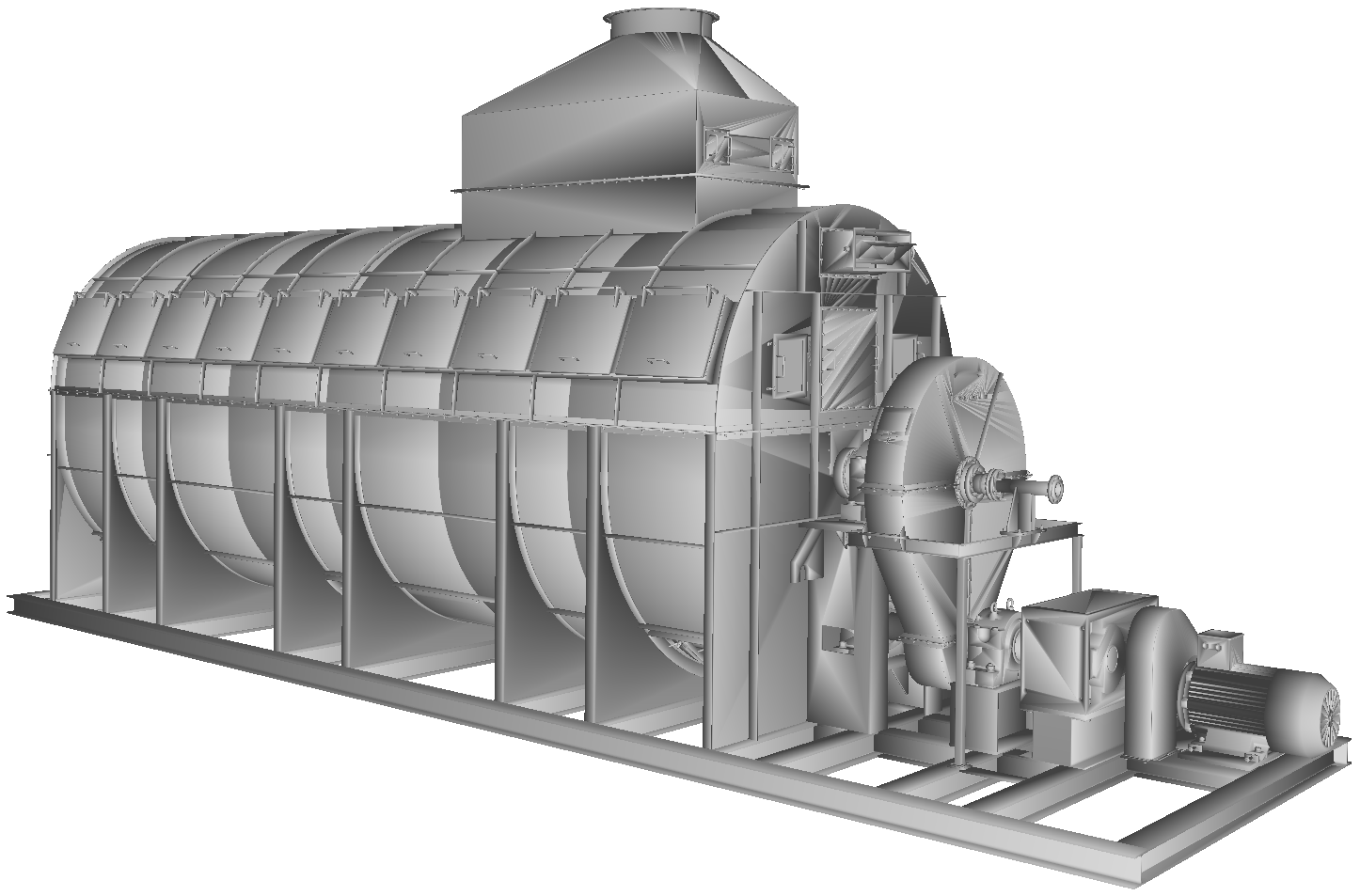

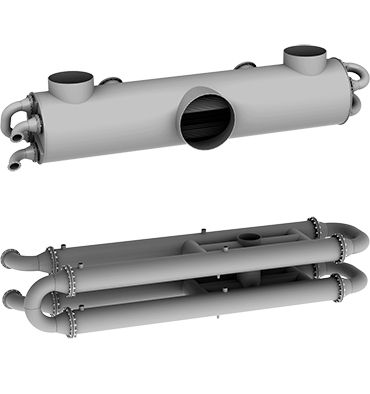

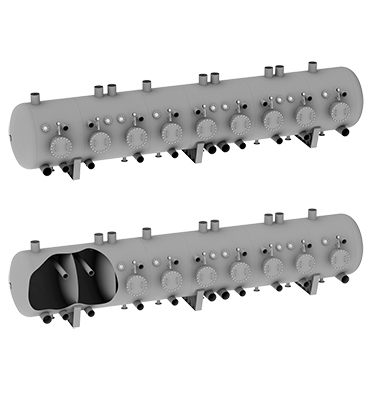

Type — horizontal dryer with tubular heat exchanger.

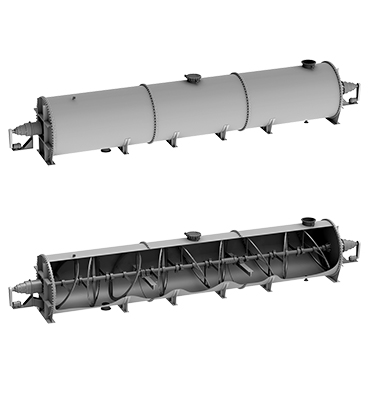

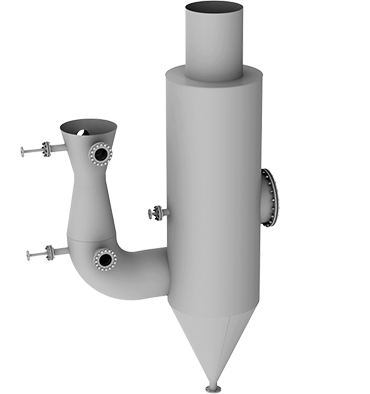

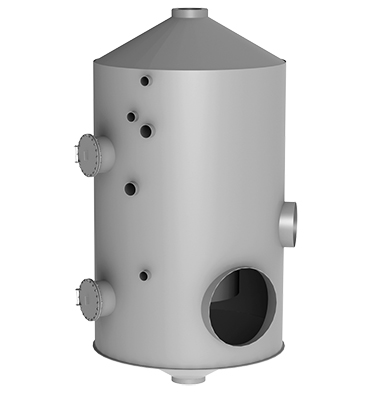

- Efficient utilization of secondary energy – evaporated moisture is incorporated into the plant’s thermal circuit;

- Maximum heat transfer due to the large surface area of tubular heating elements;

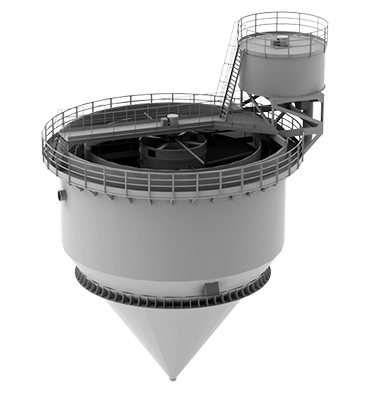

- Effective mixing and material distribution prevent the formation of stagnant zones;

- Use of wear-resistant materials in product contact areas;

- Dynamic drum balancing reduces noise and vibration;

- Thermal insulation of the shell improves energy efficiency;

- Easy maintenance thanks to convenient access to all main components.

Quality

- Uniform drying throughout the entire drum volume;

- Controlled drying modes with automatic regulation of temperature and humidity;

- Preservation of the nutritional value of feed products and other materials;

- Compliance with modern technological requirements of processing industries.

Automation

- The process control system (PCS) ensures fully automatic operation of the unit;

- Continuous monitoring and control of all key process parameters;

- Capability for integration into comprehensive production management systems (SCADA).

Specifications

| Name | TC-TBD-700 | TC-TBD-900 | TC-TBD-1000 |

| Evaporated water capacity, t/h | 3,2 | 4,2 | 4,7 |

| Heating medium temperature, °C | 152–160 | ||

| Heating medium pressure, bar | 4–5 | ||

| Specific steam consumption, t/t of evaporated moisture | 1,3–1,4 | ||

| Product outlet moisture, % | ~8–12 | ||

| Product outlet temperature, °C | 60–80 | ||

| Feed inlet temperature, °C | 85–90 | ||

| Overall dimensions, mm: | |||

| Length | 13 500 | 14 220 | 15 300 |

| Width | 3 400 | 3 790 | 4 000 |

| Height | 5 600 | 6 090 | 6 100 |

| Motor power, kW | 90 | 110 | 110 |

| Mass, kg | 53 680 | 61 000 | 68 320 |