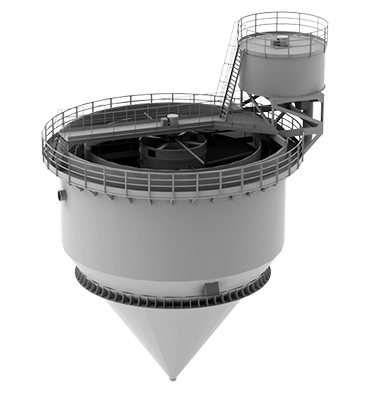

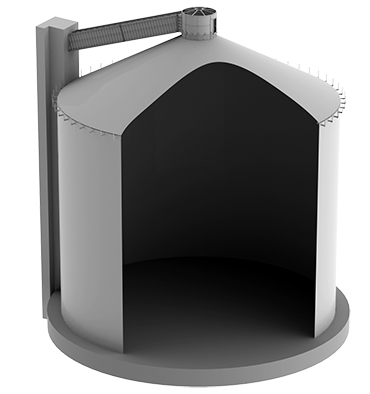

TC-SS bulk sugar storage warehouse

TC-SS bulk sugar storage warehouse

Designed for bulk long-term storage of granulated sugar with a usable capacity of 50,000 tons.

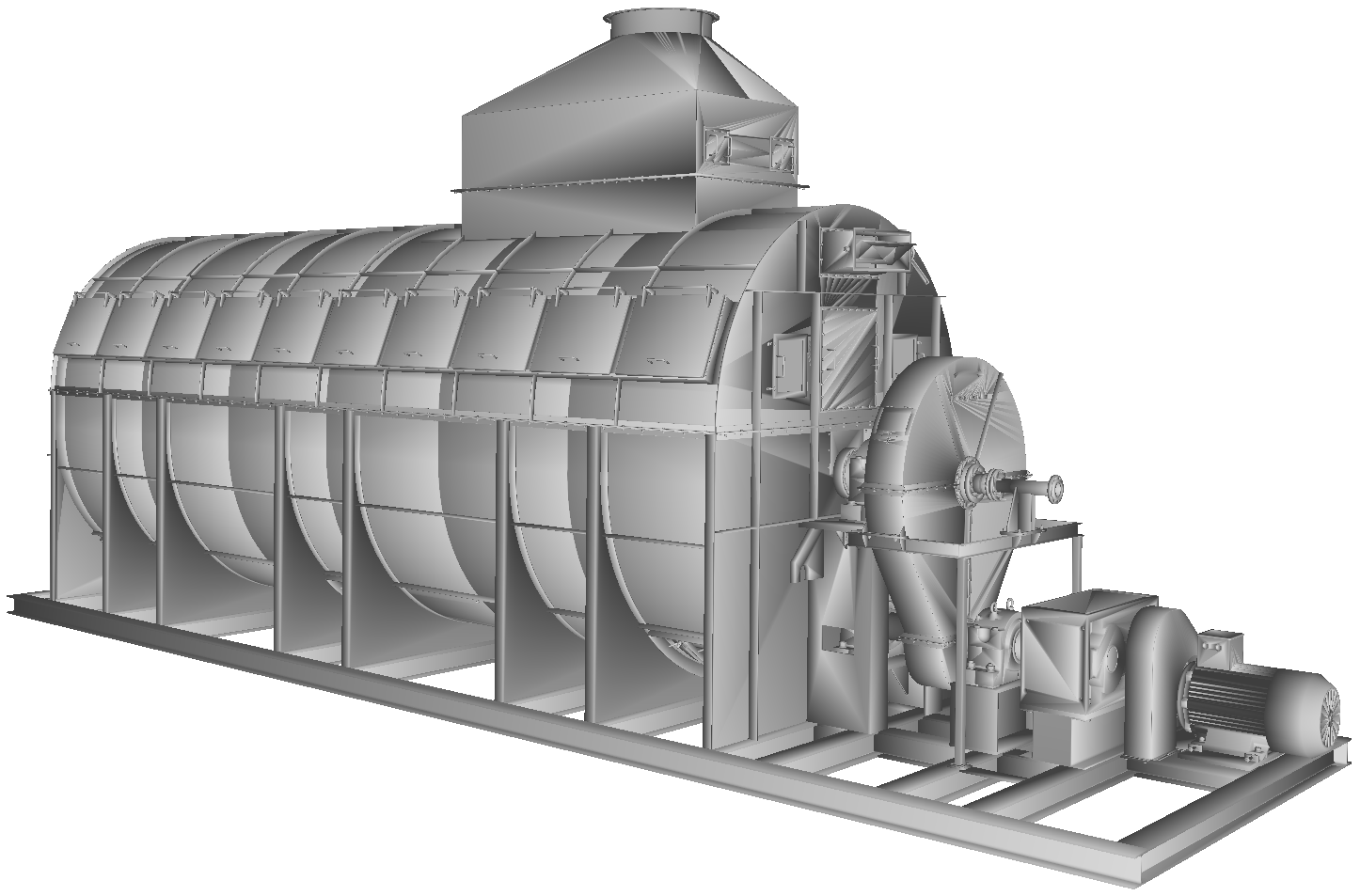

Design features

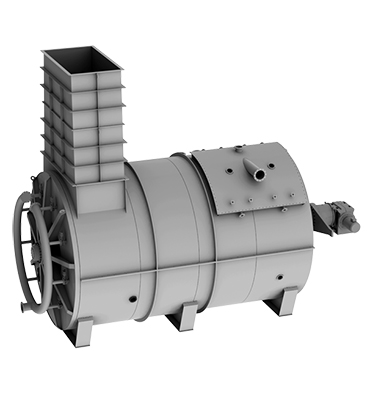

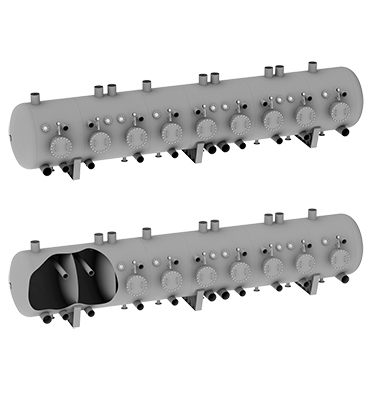

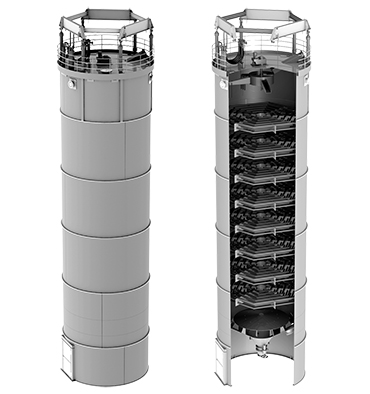

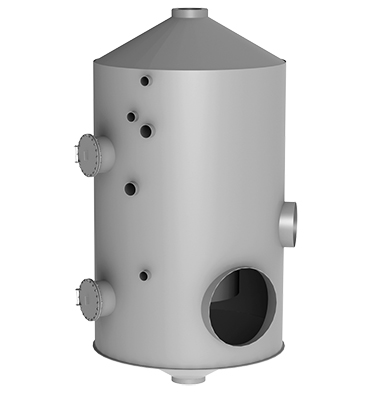

Ensuring a constant temperature of the internal walls of the silo due to the design of the cylindrical part with a hollow wall through which heated air is blown.

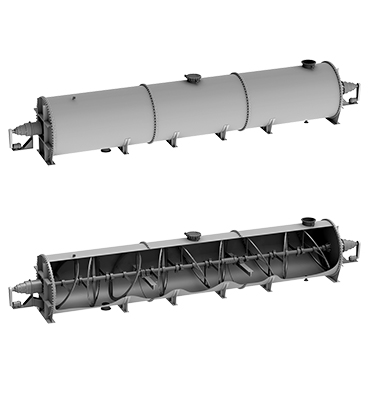

Maintaining an optimal microclimate inside the silo and removing intracrystalline moisture from sugar due to a system of pipelines in the bottom of the silo designed to supply prepared air.

Long-term storage of sugar without loss its quality.

Ensuring a technological regime to prevent sugar from sticking to the silo walls.

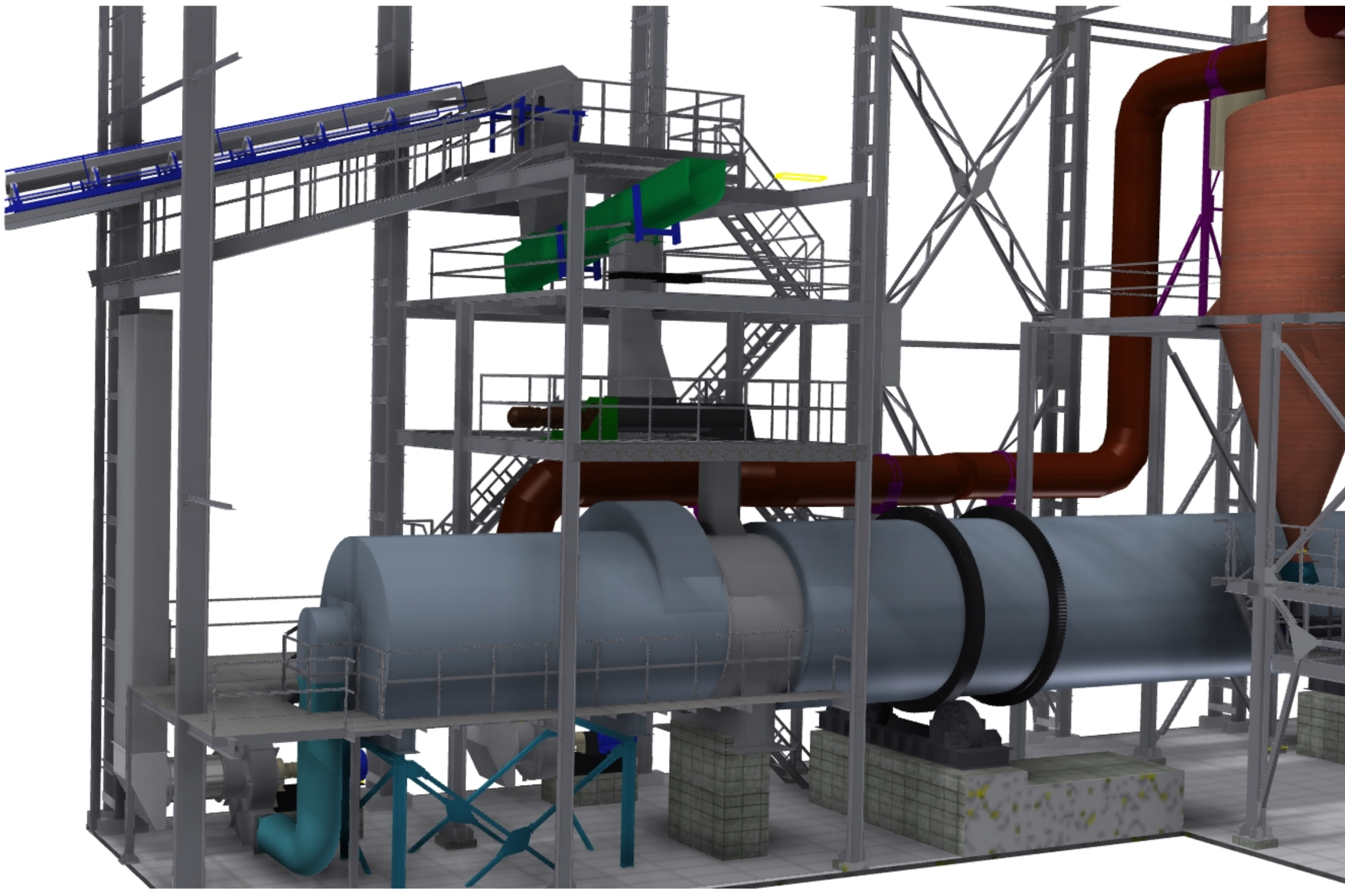

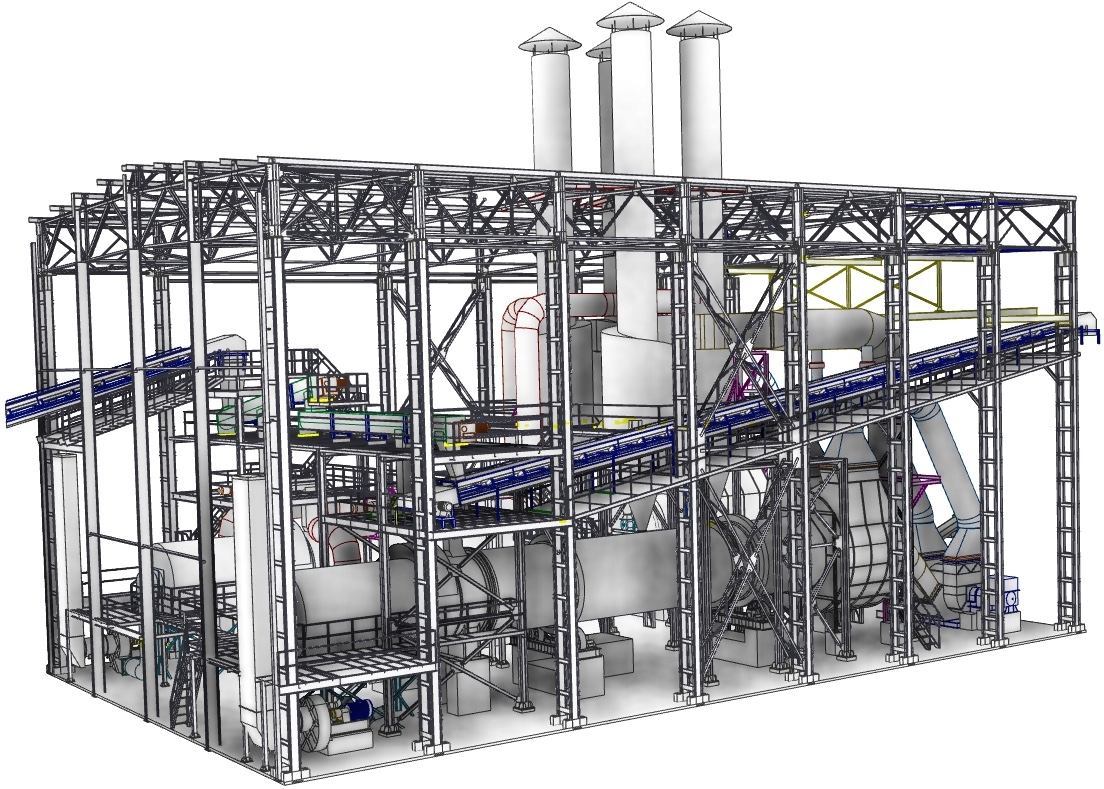

Placement of the sugar supply transport system to the silo in the gallery between the elevator tower and the sugar drying facility.

Placement of the sugar unloading system and air ducts for supplying conditioned air in the sub-silo space to maintain the temperature and humidity regime in the silo.

Presence of an engineering structure in which fans, filters, air conditioner, electrical panel and automation panels are located.

The possibility of shipment to specialized road transport or to the packaging line in various packages both during the production period and during the storage period.

The method of loading the silo is in the center.

Quality

Long-term storage of sugar without loss of its primary quality, which is almost impossible to achieve in traditional warehouses.

Economical

Reducing the cost of the silo structure and simplifying its installation by making the body, cylindrical part and bottom of metal.

Significantly smaller production area with the same amount of sugar storage compared to traditional warehouses.

The possibility of using the warehouse for several enterprises simultaneously.

Minimizing the impact of the human factor due to full automation of processes.

Automation

Providing an automatic mode for maintaining the amount, temperature and humidity of air blown through sugar, as well as the air temperature in the silo walls.

Providing an automatic mode for the loading and unloading line silo.

Parameters and fractional composition of sugar fed to the silo:

- content of fraction with a size of 0.3 mm — max 5%;

- content of fraction with a size of ≥ 0.4 mm — 90%;

- total moisture of sugar before the silo – 0.02 – 0.04%;

- temperature of sugar — up to 30°C;

- sugar should not contain lumps.

Characteristics

|

Wall type |

double metal wall with heating |

|

Storage temperature, °C |

22-27 |

|

Installed electrical equipment power, kW |

470 |

|

Silo capacity, t |

50,000 |

|

Silo diameter, mm |

45,000 |

|

Height of the cylindrical part, mm |

35,000 |

|

Height of the conical part of the roof, mm |

10,500 |

|

Total height of the silo, mm |

54 000 |