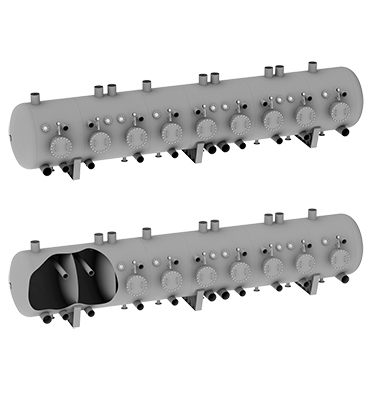

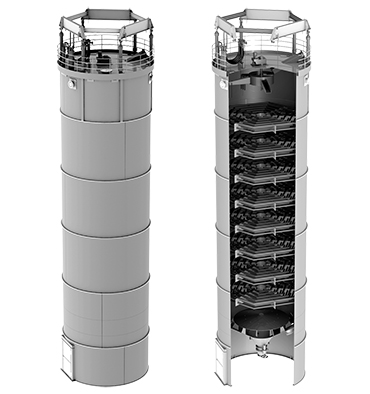

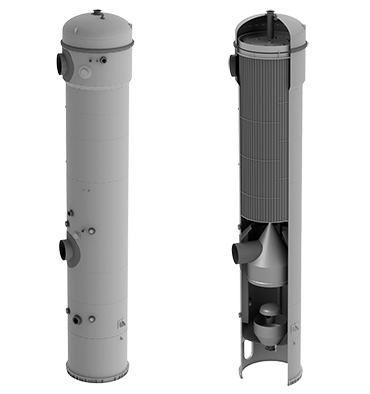

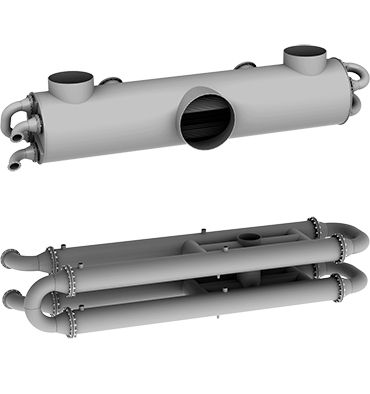

Sectional heater (heat exchanger) TC-PS

Sectional heater (heat exchanger) TC-PS

Designed for efficient heat exchange between liquids, gases, or vapors in various industrial sectors. Used for heating, cooling, condensation, or heat recovery in technological systems.

Structual features

Universal modular system with 2 to 8 sections;

Wide selection of sizes and configurations for different process requirements;

Highly efficient system for heating medium supply and removal of condensate and non-condensable gases;

Optimal balance between heat-exchange area, flow velocity, and hydraulic resistance;

Customized design according to client specifications;

Option for horizontal or vertical configuration;

Heat-exchange surface made of stainless steel (other materials available on request).

Quality

High heat-transfer coefficient and stable efficiency under variable loads;

Full utilization of heating medium energy;

Uniform flow distribution without stagnant zones;

Capability to operate with low-potential heat sources;

Optimal cost-to-efficiency ratio compared to other types of heat-exchange equipment.

Reliability

Resistance to scaling and corrosion;

Continuous operation over a wide range of temperatures and pressures;

Robust and simple construction without complex or costly components;

Convenient cleaning and maintenance.

Efficiency

Increased energy efficiency of industrial processes;

Reduced consumption of steam, water, and electricity;

Capability to use secondary energy resources;

Optimized thermal process schemes for lower energy consumption and reduced emissions.

Specifications

| Name | TC-PS-19 | TC-PS-45 | TC-PS-72 | TC-PS-101 | TC-PS-118 | TC-PS-130 | TC-PS-242 | TC-PS-320 |

| Heating surface area, m² | 19 | 45 | 72 | 101 | 118 | 130 | 242 | 320 |

| Number of sections, pcs. | 4 | 4 | 4 | 4 | 2 | 4 | 6 | 6 |

| Heat exchange tube diameter, mm | 33 | |||||||

| Heat exchange tube length, mm | 6000 | |||||||

| Mass, kg | 838 | 1 055 | 2 433 | 3 341 | 4 146 | 4 930 | 7 463 | 10 900 |