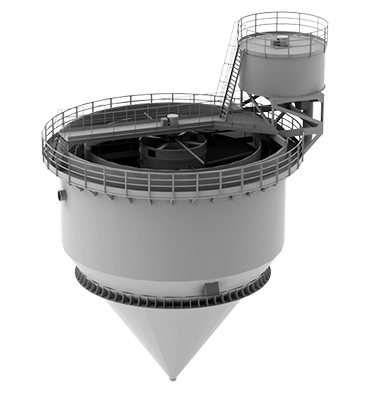

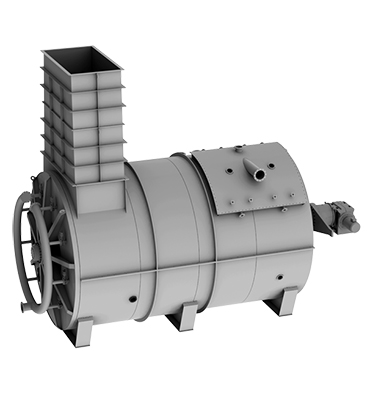

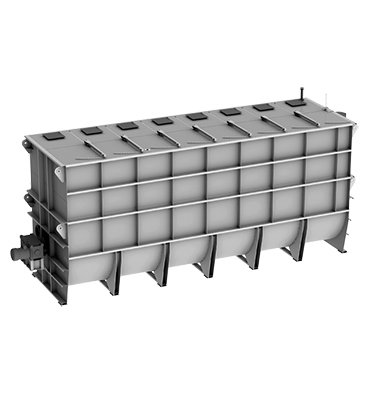

Vacuum apparatus of periodic action TC-VA

Vacuum apparatus of periodic action TC-VA

Designed for boiling massecuite of all degrees of crystallization under vacuum during processing of beet or raw sugar at sugar industry enterprises.

Design features

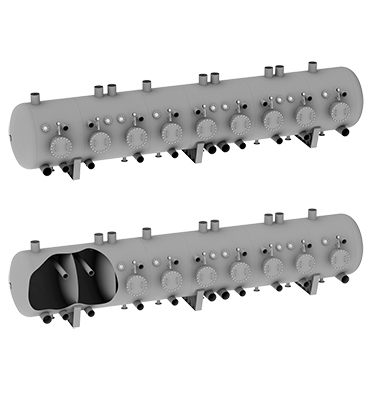

Optimization of the massecuite circulation process due to the presence of a mechanical circulator, built-in steam chamber and streamlined bottom shape.

Product supply to the apparatus directly into the circulation pipe.

Adaptation of the design for boiling using mother liquor massecuite or cold crystallized product.

Effective removal of condensate, light and heavy gases from the steam chamber.

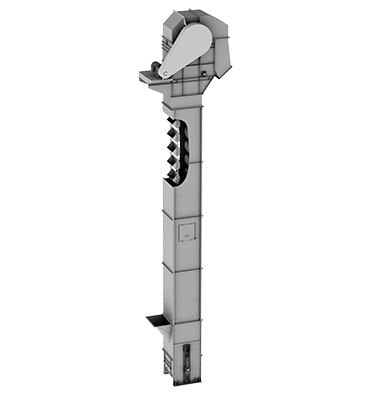

Location of the circulator actuator in the upper part of the apparatus.

Minimal hydrodynamic resistance to massecuite circulation.

Quality

Fast and efficient execution of massecuite “rolling” due to design features.

Economy

Possibility of massecuite cooking with reduced potential steam.

Reduction of massecuite cooking time due to the high heat exchange characteristics of the apparatus and the presence of a circulator.

Reliability

High reliability of the circulator, which is used for mechanical mixing and ensures intensive massecuite movement at all stages of cooking.

Reliable separation product drops from the massague steam.

No stagnant zones.

Automation

Guaranteed adaptation to the implementation of modern massague boiling automation systems.

Characteristics

|

|

ТC-VA-60 |

ТC-VA-75 |

|

Weight of cooked massif, t |

60 |

75 |

|

Useful volume of the device, m³ |

40 |

50 |

|

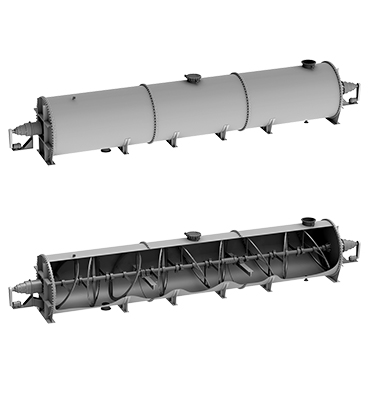

Steam chamber heating surface, m² |

317 |

400 |

|

Specific heat exchange surface, m²/t |

5.28 |

5.33 |

|

Installed capacity, kW |

60/46 |

66/35 |

|

Circulator speed, rpm. |

73/37 |

57/38 |

|

Weight, kg |

31,600 |

36,200 |

|

Inner diameter of the device, mm |

4 500 |

4 500 |

|

Dimensions — length, mm |

5 000 |